kategori Produk

BRAND

Measuring Tools

**If you don't find the product you are looking for, please chat admin via WhatsApp to check the availability of the item

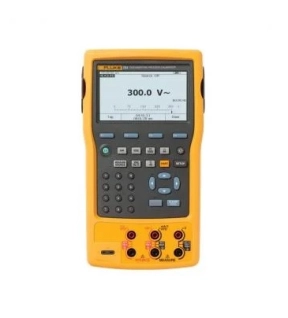

Fluke 754 Documenting Process Calibrator-HART

Portable multi-function calibrator simplifies calibration work

Whether you're calibrating instruments, troubleshooting a problem, or running routine maintenance, the Fluke 754 with HART® communication can help you get the job done faster. It does many different tasks quickly and it's the only process calibrator you need to carry. This rugged, reliable, integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART smart transmitters and other instrumentation.

Measurement and source capabilities:

- AC/DC voltage

- mA loop w/ 24V loop power

- Pressure

- Thermocouples & RTDs

- Frequency

- Resistance

Enhanced process calibrator operation

With the bright white dual display, you’ll be able to read both sourced and measured parameters simultaneously. The rechargeable Li-Ion battery offers up to 10 hours uninterrupted usage allowing you to complete one task after another without needing to stop, and also includes direct AC power capabilities if needed. Finally, communicate with HART smart digital transmitters directly through the mA measurement jacks for seamless calibration with fewer connections.

Do more, with less

The 754 does the work of several tools. It sources, simulates and measures pressure, temperature, and electrical signals with one rugged, hand-held device. The powerful built-in HART interface can perform nearly all day-to-day tasks you now perform with a separate digital communicator. It can handle fast-pulsed RTD transmitters and PLCs, with pulses as short as 1 ms. The 754 also measures/sources pressure using any of the Fluke 750P Series Pressure Modules as a reference and boasts many additional features like:

- Custom auto-step and ramping

- Custom units

- User-entered values during test

- One-point and two-point switch testing

- Square root DP flow testing

- Programmable measurement delay

Download procedures, lists, and instructions

The 754 is a power multifunction documenting calibrator that you can use to download procedures, lists, and instructions created with software, or upload data for printing, archiving, and analysis. The tool can hold up to a full week of downloaded procedures and calibration results and offers compatibility with many asset management software. Users can also create and run automated as-found or as-left procedures to satisfy quality programs or regulations, and records and documents results.

For documentation, the 754 automates calibration procedures and captures your data. And, of course, it helps you meet rigorous standards like ISO 9000, FDA, EPA, and OSHA regulations. Plus, the graphical screen, Li-Ion battery for longer life, USB port, and accessories help you work smarter and faster.

To create a seamless/paperless calibration management system consider adding Fluke DPCTrack2 Calibration Management software.

Whether you're calibrating instruments, troubleshooting a problem, or running routine maintenance, the Fluke 754 with HART® communication can help you get the job done faster. It does many different tasks quickly and it's the only process calibrator you need to carry. This rugged, reliable, integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART smart transmitters and other instrumentation.

Measurement and source capabilities:

- AC/DC voltage

- mA loop w/ 24V loop power

- Pressure

- Thermocouples & RTDs

- Frequency

- Resistance

Enhanced process calibrator operation

With the bright white dual display, you’ll be able to read both sourced and measured parameters simultaneously. The rechargeable Li-Ion battery offers up to 10 hours uninterrupted usage allowing you to complete one task after another without needing to stop, and also includes direct AC power capabilities if needed. Finally, communicate with HART smart digital transmitters directly through the mA measurement jacks for seamless calibration with fewer connections.

Do more, with less

The 754 does the work of several tools. It sources, simulates and measures pressure, temperature, and electrical signals with one rugged, hand-held device. The powerful built-in HART interface can perform nearly all day-to-day tasks you now perform with a separate digital communicator. It can handle fast-pulsed RTD transmitters and PLCs, with pulses as short as 1 ms. The 754 also measures/sources pressure using any of the Fluke 750P Series Pressure Modules as a reference and boasts many additional features like:

- Custom auto-step and ramping

- Custom units

- User-entered values during test

- One-point and two-point switch testing

- Square root DP flow testing

- Programmable measurement delay

Download procedures, lists, and instructions

The 754 is a power multifunction documenting calibrator that you can use to download procedures, lists, and instructions created with software, or upload data for printing, archiving, and analysis. The tool can hold up to a full week of downloaded procedures and calibration results and offers compatibility with many asset management software. Users can also create and run automated as-found or as-left procedures to satisfy quality programs or regulations, and records and documents results.

For documentation, the 754 automates calibration procedures and captures your data. And, of course, it helps you meet rigorous standards like ISO 9000, FDA, EPA, and OSHA regulations. Plus, the graphical screen, Li-Ion battery for longer life, USB port, and accessories help you work smarter and faster.

To create a seamless/paperless calibration management system consider adding Fluke DPCTrack2 Calibration Management software.

Fluke 789 ProcessMeter™

Double your strength

The Fluke 787 was the first device to combine a DMM and a loop calibrator to give process technicians double the power in one tool. Now even better, range is extended in the Fluke 789 – the ultimate loop calibration multimeter. The Fluke 789 has a 24-Volt supply loop which eliminates the need to take a separate power supply when testing transmitters offline. And with selectable onboard 250-Ohm Hart® resistors, the need to carry separate resistors is eliminated. Now process engineers can do more while carrying far less.

The Fluke 787 was the first device to combine a DMM and a loop calibrator to give process technicians double the power in one tool. Now even better, range is extended in the Fluke 789 – the ultimate loop calibration multimeter. The Fluke 789 has a 24-Volt supply loop which eliminates the need to take a separate power supply when testing transmitters offline. And with selectable onboard 250-Ohm Hart® resistors, the need to carry separate resistors is eliminated. Now process engineers can do more while carrying far less.

Fluke Fluke ii500 Acoustic Imager

Fluke ii500 Acoustic Imager with LeakQ™: Detect, Locate, and Capture Gas Leaks

The Fluke ii500 Acoustic Imager, equipped with LeakQ™ technology, empowers maintenance teams to detect and locate gas leaks efficiently. Designed for ease of use, it requires no specialized training. Even during peak production periods, teams can effectively identify gas and vacuum leaks. The ii500's advanced acoustic leak detection technology isolates leak sound frequencies, making leaks visible even in noisy environments.

Key features

• Ready-to-Use: The Fluke ii500 is ready out of the box. Its rugged, ergonomic design ensures easy handling, while the large 7" LCD display allows for clear leak visualization.

• Quick Detection: Even users with minimal experience can start detecting leaks within minutes. The tool estimates relative leak size and cost, incorporating a new distance-estimation feature and the 1-10 LeakQ™ severity index.

• SoundMap™ Overlay: The 7" LCD touchscreen overlays a SoundMap™ on visual images, facilitating rapid leak location identification.

• Intuitive Interface: Easily isolate leak sound frequencies and filter out background noise.

• Tagging and Organization: Use image and video tagging, annotation, and folders for efficient organization.

• Leak Sizing: Prioritize repairs based on relative leak size.

• Collaboration: The reporting tool allows sharing of visuals, tagging, and notes with team members and repair personnel.

The Fluke ii500 Acoustic Imager, equipped with LeakQ™ technology, empowers maintenance teams to detect and locate gas leaks efficiently. Designed for ease of use, it requires no specialized training. Even during peak production periods, teams can effectively identify gas and vacuum leaks. The ii500's advanced acoustic leak detection technology isolates leak sound frequencies, making leaks visible even in noisy environments.

Key features

• Ready-to-Use: The Fluke ii500 is ready out of the box. Its rugged, ergonomic design ensures easy handling, while the large 7" LCD display allows for clear leak visualization.

• Quick Detection: Even users with minimal experience can start detecting leaks within minutes. The tool estimates relative leak size and cost, incorporating a new distance-estimation feature and the 1-10 LeakQ™ severity index.

• SoundMap™ Overlay: The 7" LCD touchscreen overlays a SoundMap™ on visual images, facilitating rapid leak location identification.

• Intuitive Interface: Easily isolate leak sound frequencies and filter out background noise.

• Tagging and Organization: Use image and video tagging, annotation, and folders for efficient organization.

• Leak Sizing: Prioritize repairs based on relative leak size.

• Collaboration: The reporting tool allows sharing of visuals, tagging, and notes with team members and repair personnel.

Fluke Fluke ii915 Acoustic Imager

Fluke ii915 Acoustic Imager: Detect, Locate, and Assess Anomalies

The Fluke ii915 Acoustic Imager is a powerful tool designed to identify and evaluate issues in various systems. With three distinct modes—LeakQ™, PDQ™, and MecQ™—this innovative device empowers maintenance professionals to take proactive measures and prevent costly problems. Let’s explore its capabilities:

Leak Detection with More Sensitivity

LeakQ™ Mode: Detect Hidden Costs

Leaks in compressed air, gas, steam, and vacuum systems can lead to significant financial losses. The Fluke ii915 simplifies leak detection by allowing technicians to visualize sound. As they scan hoses, fittings, and connections, the built-in acoustic array captures decibel levels per frequency. The resulting SoundMap™ overlays on a visual image, making it easy to pinpoint leaks—even during peak operation hours. Say goodbye to time-consuming inspections and hello to efficient leak detection. Fluke ii915 has the high frequency range and best sensitivity to do acoustic leak detection more efficiently.

Early Mechanical Issue Identification

MecQ™ Mode: Efficient Inspection for Conveyor Systems

Conveyor systems are notorious for their complexity and potential to disrupt production. The Fluke ii915 acoustic camera revolutionizes inspection by enabling contactless scanning of large areas. Advanced noise filtering ensures clear images, even in high-noise environments. Detecting potential mechanical issues early allows targeted maintenance, preventing unplanned downtime. For seamless operation and proactive maintenance of large conveyance systems, the Fluke ii915 Acoustic Imager with MecQ™ is the ultimate choice.

Visualizing the Invisible Threat

PDQ™ Mode: Locating Partial Discharge

Partial discharge poses serious risks, from arc flash fires to blackouts. The Fluke ii915 translates partial discharge sounds into visuals, precisely pinpointing their location. With an extended frequency range of 2-100 kHz, this tool can detect partial discharge even earlier and aids maintenance planning to prevent catastrophic events. High-voltage electricians, electrical test engineers, and grid maintenance teams can now see what was once invisible.

Key features

• Enhanced Performance: Improved detection performance for gas leaks, electrical discharges, and mechanical issues.

• LeakQ™ Mode: Estimated leak size and cost.

• PDQ Mode™: Assesses discharge severity.

• MecQ™ Mode: Proactively address potential problems in rotating mechanical components.

• Reporting Features: Integrated visual and textual tagging and annotation functionalities for streamlined reporting.

• Wireless Upload: Easily transfer data to Fluke Connect.

The Fluke ii915 Acoustic Imager is a powerful tool designed to identify and evaluate issues in various systems. With three distinct modes—LeakQ™, PDQ™, and MecQ™—this innovative device empowers maintenance professionals to take proactive measures and prevent costly problems. Let’s explore its capabilities:

Leak Detection with More Sensitivity

LeakQ™ Mode: Detect Hidden Costs

Leaks in compressed air, gas, steam, and vacuum systems can lead to significant financial losses. The Fluke ii915 simplifies leak detection by allowing technicians to visualize sound. As they scan hoses, fittings, and connections, the built-in acoustic array captures decibel levels per frequency. The resulting SoundMap™ overlays on a visual image, making it easy to pinpoint leaks—even during peak operation hours. Say goodbye to time-consuming inspections and hello to efficient leak detection. Fluke ii915 has the high frequency range and best sensitivity to do acoustic leak detection more efficiently.

Early Mechanical Issue Identification

MecQ™ Mode: Efficient Inspection for Conveyor Systems

Conveyor systems are notorious for their complexity and potential to disrupt production. The Fluke ii915 acoustic camera revolutionizes inspection by enabling contactless scanning of large areas. Advanced noise filtering ensures clear images, even in high-noise environments. Detecting potential mechanical issues early allows targeted maintenance, preventing unplanned downtime. For seamless operation and proactive maintenance of large conveyance systems, the Fluke ii915 Acoustic Imager with MecQ™ is the ultimate choice.

Visualizing the Invisible Threat

PDQ™ Mode: Locating Partial Discharge

Partial discharge poses serious risks, from arc flash fires to blackouts. The Fluke ii915 translates partial discharge sounds into visuals, precisely pinpointing their location. With an extended frequency range of 2-100 kHz, this tool can detect partial discharge even earlier and aids maintenance planning to prevent catastrophic events. High-voltage electricians, electrical test engineers, and grid maintenance teams can now see what was once invisible.

Key features

• Enhanced Performance: Improved detection performance for gas leaks, electrical discharges, and mechanical issues.

• LeakQ™ Mode: Estimated leak size and cost.

• PDQ Mode™: Assesses discharge severity.

• MecQ™ Mode: Proactively address potential problems in rotating mechanical components.

• Reporting Features: Integrated visual and textual tagging and annotation functionalities for streamlined reporting.

• Wireless Upload: Easily transfer data to Fluke Connect.

Fluke Fluke 831 Laser Shaft Alignment Tool

Precision laser alignment made easy

The rugged Fluke 831 has an intuitive guided user interface that enables quick and complete shaft alignment without advanced training or complicated programs. And while it’s easy to use, laser alignment with the Fluke 831 is powerful enough for the skilled technician. You can cover more of your machines with all the functionality needed on the plant floor, from thermal growth to user defined tolerances and more.

Reduce costs by avoiding downtime

Misalignment causes at least half of all damage to rotating machinery, studies show. Instead of fixing the problem, teams often just treat the symptoms of misalignment and replace bearings, couplings, and seals because they think alignment takes too long.

Contrary to expectations, laser alignment can be fast and easy. So, every machine that is repaired and overhauled should be aligned – not just a few. Teams that embrace laser alignment can save thousands of dollars per year by avoiding downtime and energy waste and reducing the number of bearings and seals they have to replace.

Key features

• Fast, easy, and precise alignment that adapts to your needs.

• Rugged build and the highest-in-class IP rating.

• Single-laser technology for the fastest, most accurate laser alignment.

• Cloud connection enables real-time collaboration.

• Use up to 8 measurement points to achieve precision alignment on vertical machines.

The rugged Fluke 831 has an intuitive guided user interface that enables quick and complete shaft alignment without advanced training or complicated programs. And while it’s easy to use, laser alignment with the Fluke 831 is powerful enough for the skilled technician. You can cover more of your machines with all the functionality needed on the plant floor, from thermal growth to user defined tolerances and more.

Reduce costs by avoiding downtime

Misalignment causes at least half of all damage to rotating machinery, studies show. Instead of fixing the problem, teams often just treat the symptoms of misalignment and replace bearings, couplings, and seals because they think alignment takes too long.

Contrary to expectations, laser alignment can be fast and easy. So, every machine that is repaired and overhauled should be aligned – not just a few. Teams that embrace laser alignment can save thousands of dollars per year by avoiding downtime and energy waste and reducing the number of bearings and seals they have to replace.

Key features

• Fast, easy, and precise alignment that adapts to your needs.

• Rugged build and the highest-in-class IP rating.

• Single-laser technology for the fastest, most accurate laser alignment.

• Cloud connection enables real-time collaboration.

• Use up to 8 measurement points to achieve precision alignment on vertical machines.