kategori Produk

BRAND

FlukeKennedyMilwaukeeMakitaYorkBottKobe3MSealeyFlexovitSherwoodGranlundDragerGysSitesafeMatlockSenatorSuper StrengthChicago PneumaticPanasonicYamotoKennedy-ProSummitechWD 40KengripSwissBurrEdisonSolent Spill ControlKennedy Red-Hot-DipKobe Blue LineKobe Red LineHaloTuffsafeIndexaAvonYamaloyCotswoldSwisstechAtlas WorkhokdersThorOxfordRutlandCheetahMaster LockESABCIGWELDMorescoDiscfloCRCGastronMSASiemensISCSchneider

Produk

Kategori Produk

York SB0202CT, Sanding Band, 75 x 30mm, P150, Aluminium Oxide

Spiral wound with tear-resistant backing fabric.

Features and Benefits

• For grinding and finishing edges, profiles, welded seams.

• To be used on designated rubber drum holder

• Maximum permitted peripheral speed of 30m/s

• P60 = Coarse, P80 = Medium, P150 = Fine.

Features and Benefits

• For grinding and finishing edges, profiles, welded seams.

• To be used on designated rubber drum holder

• Maximum permitted peripheral speed of 30m/s

• P60 = Coarse, P80 = Medium, P150 = Fine.

York SB0213CT, Sanding Band, 100 x 40mm, P60, Aluminium Oxide

Spiral wound with tear-resistant backing fabric.

Features and Benefits

• For grinding and finishing edges, profiles, welded seams.

• To be used on designated rubber drum holder

• Maximum permitted peripheral speed of 30m/s

• P60 = Coarse, P80 = Medium, P150 = Fine.

Features and Benefits

• For grinding and finishing edges, profiles, welded seams.

• To be used on designated rubber drum holder

• Maximum permitted peripheral speed of 30m/s

• P60 = Coarse, P80 = Medium, P150 = Fine.

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 3mm, Conical

Conical Shape.

All sizes are nominal with a 6mm shank unless other wise stated.

Cut Numbers:

Cut 6 - Double Cut.

Crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

All sizes are nominal with a 6mm shank unless other wise stated.

Cut Numbers:

Cut 6 - Double Cut.

Crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

York SB0214CT, Sanding Band, 100 x 40mm, P80, Aluminium Oxide

Spiral wound with tear-resistant backing fabric.

Features and Benefits

• For grinding and finishing edges, profiles, welded seams.

• To be used on designated rubber drum holder

• Maximum permitted peripheral speed of 30m/s

• P60 = Coarse, P80 = Medium, P150 = Fine.

Features and Benefits

• For grinding and finishing edges, profiles, welded seams.

• To be used on designated rubber drum holder

• Maximum permitted peripheral speed of 30m/s

• P60 = Coarse, P80 = Medium, P150 = Fine.

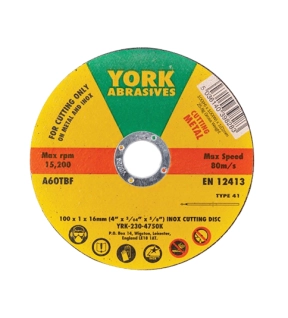

York Cutting Disc, 60-Fine, 100 x 1 x 16 mm, Type 41, Aluminium Oxide

York Inox cutting discs are perfect for efficiently cutting metal with minimum material removal and machine wear, thanks to their thin profile. They are suitable for use with all appropriate handheld grinders and can even be used on stainless steel.

There are a wide range of sizes available, with 180mm and 230mm sizes suitable for use on circular saws.

Features and Benefits

• Thin profile allows for quick and efficient cuts with minimal material removal and machine wear

• Wide range of sizes allow for usage on a variety of appropriate handheld grinders and larger sizes can even be used in circular saws

Notes

• Cutting discs must never be used for grinding and must always be presented to the work piece at an angle of 90°

There are a wide range of sizes available, with 180mm and 230mm sizes suitable for use on circular saws.

Features and Benefits

• Thin profile allows for quick and efficient cuts with minimal material removal and machine wear

• Wide range of sizes allow for usage on a variety of appropriate handheld grinders and larger sizes can even be used in circular saws

Notes

• Cutting discs must never be used for grinding and must always be presented to the work piece at an angle of 90°

York Coated Disc, 150mm, Aluminium Oxide, P60, Hook & Loop

100% of these hook-n-loop sanding discs can be used.

Features and Benefits

• Can be removed and re-applied and unaffected by dust or moisture

• Aluminium oxide abrasive 'resin-bonded over resin' to hook-n-loop backed paper is suitable for wood, plastics, ceramics

Typical Applications

• Wood industry

• Plastics industry

Features and Benefits

• Can be removed and re-applied and unaffected by dust or moisture

• Aluminium oxide abrasive 'resin-bonded over resin' to hook-n-loop backed paper is suitable for wood, plastics, ceramics

Typical Applications

• Wood industry

• Plastics industry

York 100x16mm F/GLASS ZIRC FLAP DISC P120

York conical flap discs are a high performance alternative to sanding discs with the advantage over depressed centre grinding discs on light gauge sheet metal where surface finish is important. The overlapped abrasive material wear away revealing fresh abrasive, ensuring the discs always cuts effectively and reduces clogging and providing a consistent finish throughout the disc life. The fibre backing allows for use without backing pads and makes the discs safe to use on any grinder up 80m/s speeds.

Features and Benefits

• Overlapped abrasive material wear away to reveal fresh abrasive ensuring effective cuts and reduces clogging

• Fibre backing allows for use without backing pads and makes the discs safe for use on any grinder

Typical Applications

• Construction

• Automotive

• Manufacturing

Standards

• EN12413

Features and Benefits

• Overlapped abrasive material wear away to reveal fresh abrasive ensuring effective cuts and reduces clogging

• Fibre backing allows for use without backing pads and makes the discs safe for use on any grinder

Typical Applications

• Construction

• Automotive

• Manufacturing

Standards

• EN12413

York Carbide Burr, Uncoated, Cut 9 - Chipbreaker, 3mm, Cylindrical End Cut

Cylindrical-End Cutting

All sizes are nominal with a 6mm shank unless other wise stated.

Cut Numbers:

Cut 3 - Rapid Cut.

for use on softer non ferrous and plastic materials, i.e aluminium, fibreglass, plastics, hard rubber and zinc alloy,

Cut 6 - Double Cut.

Crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

All sizes are nominal with a 6mm shank unless other wise stated.

Cut Numbers:

Cut 3 - Rapid Cut.

for use on softer non ferrous and plastic materials, i.e aluminium, fibreglass, plastics, hard rubber and zinc alloy,

Cut 6 - Double Cut.

Crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

York Flap Wheel, 30 x 15mm, P80, Aluminium Oxide, 6mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

York Flap Wheel, 40 x 20mm, P40, Aluminium Oxide, 6mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

York Carbide Burr, Uncoated, Cut 9 - Chipbreaker, 9.5mm, Cylindrical Plain End

Cut-9 chipbreaker rotary burrs are designed for fast stock removal and improved control for reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Features and Benefits

• Solid carbide construction

• Enables fast stock removal on hard materials

• Allows for improved control and reduced chips

Typical Applications

• Deburring

• Polishing

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

up to HRC65 hardness.

Notes

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Features and Benefits

• Solid carbide construction

• Enables fast stock removal on hard materials

• Allows for improved control and reduced chips

Typical Applications

• Deburring

• Polishing

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

up to HRC65 hardness.

Notes

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

York Flap Wheel, 50 x 15mm, P80, Aluminium Oxide, 6mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only