Measuring Tools

Fluke 721 Pressure Calibration Instruments

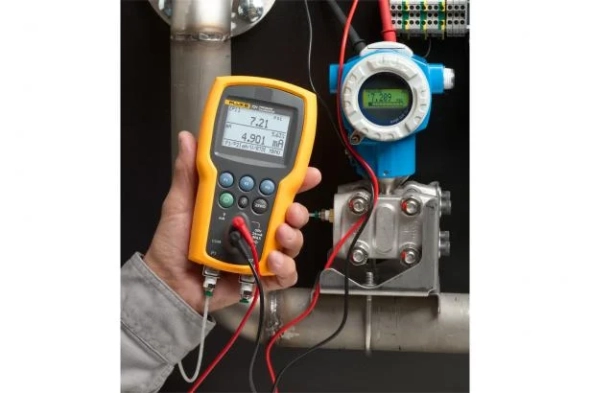

Fluke 721 Precision Pressure Calibrator provides pressure calibration and temperature measurement for custody transfer applications

The Fluke 721 Precision Pressure Calibrator is the ideal tool for gas custody transfer applications. It features dual isolated pressure sensors to allow you to take simultaneous static and differential pressure measurements with a single tool. And it can be configured by selecting either a 16 psi (1.1 bar) or 36 psi (2.48 bar) low pressure sensor then adding any of seven high pressure ranges: 100, 300, 500, 1000, 1500, 3000 or 5000 psi (6.9, 20, 24.5, 69, 103.4, 200, 345 bar).

Other useful features:

- Measures up to 30 V DC, checks 24 V loop power supplies

- Extends pressure measurement range with connection to external 750P

- 750 series pressure modules (50 ranges)

- Provides a large backlit graphic display that can show up to three inputs simultaneously

- Stores five instrument setups for recall

The Fluke 721 Precision Pressure Calibrator is the ideal tool for gas custody transfer applications. It features dual isolated pressure sensors to allow you to take simultaneous static and differential pressure measurements with a single tool. And it can be configured by selecting either a 16 psi (1.1 bar) or 36 psi (2.48 bar) low pressure sensor then adding any of seven high pressure ranges: 100, 300, 500, 1000, 1500, 3000 or 5000 psi (6.9, 20, 24.5, 69, 103.4, 200, 345 bar).

Other useful features:

- Measures up to 30 V DC, checks 24 V loop power supplies

- Extends pressure measurement range with connection to external 750P

- 750 series pressure modules (50 ranges)

- Provides a large backlit graphic display that can show up to three inputs simultaneously

- Stores five instrument setups for recall

Download

Products Lainnya

Fluke 9100S, 9102S Handheld Dry-Wells

World’s smallest, lightest and most portable dry-wells

• Smallest dry-wells in the world

• Ranges from –10°C to 375°C

• Accuracy to ±0.25°C, stability of ±0.05°C at 0°C

• RS-232 interface

Fluke Calibration's line of portable dry-wells is incredible. They’re the smallest, lightest, and most portable dry-wells in the world. And now they're better than ever!

• Smallest dry-wells in the world

• Ranges from –10°C to 375°C

• Accuracy to ±0.25°C, stability of ±0.05°C at 0°C

• RS-232 interface

Fluke Calibration's line of portable dry-wells is incredible. They’re the smallest, lightest, and most portable dry-wells in the world. And now they're better than ever!

Fluke 6109A / 7109A Portable Calibration Baths

Key features

• Calibrate up to four tri-clamp sanitary sensors per batch with ± 0.1 °C temperature display accuracy.

• Covers a wide temperature range: 6109A: 35 °C to 250 °C

• 7109A: -25 °C to 140 °C.

• Stainless steel casing that withstands harsh cleaning solutions; it's easy to transport and maintain.

• Calibrate up to four tri-clamp sanitary sensors per batch with ± 0.1 °C temperature display accuracy.

• Covers a wide temperature range: 6109A: 35 °C to 250 °C

• 7109A: -25 °C to 140 °C.

• Stainless steel casing that withstands harsh cleaning solutions; it's easy to transport and maintain.

Fluke VT06 Visual IR Thermometer

Fluke VT series is built with legendary Fluke ruggedness and quality. With compact design and upgraded function, the temperature measurement is visualized, so that you can obtain a clear and accurate infrared thermal image.

Fluke 568 Ex Intrinsically Safe Mini Infrared Thermometer

Use the Fluke 568 Ex for intrinsically safe temperature measurements anywhere in the world

The Fluke 568 Ex Intrinsically Safe Infrared Thermometer is certified by major rating bodies for use in Class I Div. 1 and Div. 2 or Zone 1 and 2 hazardous environments anywhere in the world. Whether you work in petroleum, chemical, oil and gas, or pharmaceutical environments, the 568 Ex allows you to carry the most trusted name in test tools into most Ex-rated areas around the globe. The simple, three-button on-screen menu interface is quick to use and makes even complex measurements easy. It takes just a few pushes of a button to adjust emissivity, record data, or turn on and off alarms. The 50:1 distance-to-spot ratio allows you to measure smaller objects from further away. And it also is compatible with K-type probes for contact measurements. Either way, you can count on the rugged, ergonomic design to stand up to tough conditions.

Other useful features:

- Instantly alerts you to measurements outside of set limits with audible and visual alarms

- Provides with 1% measurement accuracy

- Comes with thermocouple K bead probe and two-year warranty -30-

- Features a rugged, easy-to-use, ergonomic design that stands up to tough industrial, electrical, and mechanical environments

- Works with mini-connector K-type thermocouples

- Allows easy access to advanced features with soft-key buttons and graphical display

- Captures up to 99 points of data for quick downloading to a PC through the USB connection

- Powered by two AA batteries

- Allows you to confidently measure a wide variety of surfaces with adjustable emissivity and built-in materials table

- Easily adapts to lighting conditions with a two-level backlight

The Fluke 568 Ex Intrinsically Safe Infrared Thermometer is certified by major rating bodies for use in Class I Div. 1 and Div. 2 or Zone 1 and 2 hazardous environments anywhere in the world. Whether you work in petroleum, chemical, oil and gas, or pharmaceutical environments, the 568 Ex allows you to carry the most trusted name in test tools into most Ex-rated areas around the globe. The simple, three-button on-screen menu interface is quick to use and makes even complex measurements easy. It takes just a few pushes of a button to adjust emissivity, record data, or turn on and off alarms. The 50:1 distance-to-spot ratio allows you to measure smaller objects from further away. And it also is compatible with K-type probes for contact measurements. Either way, you can count on the rugged, ergonomic design to stand up to tough conditions.

Other useful features:

- Instantly alerts you to measurements outside of set limits with audible and visual alarms

- Provides with 1% measurement accuracy

- Comes with thermocouple K bead probe and two-year warranty -30-

- Features a rugged, easy-to-use, ergonomic design that stands up to tough industrial, electrical, and mechanical environments

- Works with mini-connector K-type thermocouples

- Allows easy access to advanced features with soft-key buttons and graphical display

- Captures up to 99 points of data for quick downloading to a PC through the USB connection

- Powered by two AA batteries

- Allows you to confidently measure a wide variety of surfaces with adjustable emissivity and built-in materials table

- Easily adapts to lighting conditions with a two-level backlight