Cutting Tools

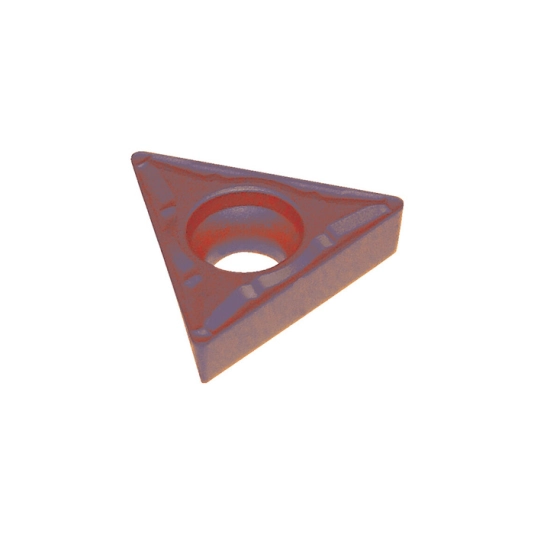

Yamaloy TCMT 16T304-PM, Turning Insert, Grade QX500, Cermet, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Download

Products Lainnya

Swisstech Jobber Drill, 7mm, High Helix, Cobalt High Speed Steel, TiN

Series 1060 HSS-Co Straight Shank High Helix Jobber Drills

TiN Coated - Metric

Heavy duty drill for stainless steel, heat and acid-resistant steels, short chipping and high strength steels. High heat resistance allows drilling in titanium and titanium alloys. TiN coating provides longer tool life.

Point angle: 130°. Helix angle: high. Web thickness: strengthened. Relief angle: normal.

Tolerance of diameter: h8. Tolerance of shank: f11. Manufactured to DIN 338RN

TiN Coated - Metric

Heavy duty drill for stainless steel, heat and acid-resistant steels, short chipping and high strength steels. High heat resistance allows drilling in titanium and titanium alloys. TiN coating provides longer tool life.

Point angle: 130°. Helix angle: high. Web thickness: strengthened. Relief angle: normal.

Tolerance of diameter: h8. Tolerance of shank: f11. Manufactured to DIN 338RN

Kennedy Jobber Drill, 3.5mm, Normal Helix, Cobalt High Speed Steel, Bronze Oxide

The Kennedy range of HSS-Co heavy duty straight shank jobber drills provide durable and reliable cutting performance at high temperatures and speeds thanks to the addition of 5% cobalt to their alloys. Their toughness and heat resistance allows them to to drill steels with tensile strength up to 1,400 N/mm², very hard bronze, stainless steels as well as heat and acid resistant steels.

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm

Yamaloy CNMG 120404-NM6, Turning Insert, Grade QX5030, Carbide, 80° Rhombic

CNMG Turning Inserts

80° Rhombic Insert

Insert Grade QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: NM6. Application: Med Cut.

80° Rhombic Insert

Insert Grade QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: NM6. Application: Med Cut.

Sherwood Step Drill, 4 to 20, High Speed Steel

HSS multi diameter step drills produce good quality holes in a wide variety of sheet metal, using either a bench drill or light pedestal drilling machine. Manufactured from high speed steel, they offer sound rigidity, strength and stability when machining. Each tool cuts parallel holes in a range of specific sizes and is compatible with materials up to 1/8" (3mm) thick.

Features and Benefits

• High speed steel construction for greater strength, rigidity and stability

• Excellent wear and heat resistance for prolonged tool life

• Cuts parallel holes in sheet metal

Typical Applications

• Drilling

• Sheet metal

Notes

• Available sizes 1-12mm to 6-37mm

Features and Benefits

• High speed steel construction for greater strength, rigidity and stability

• Excellent wear and heat resistance for prolonged tool life

• Cuts parallel holes in sheet metal

Typical Applications

• Drilling

• Sheet metal

Notes

• Available sizes 1-12mm to 6-37mm