Pump & Lubricants

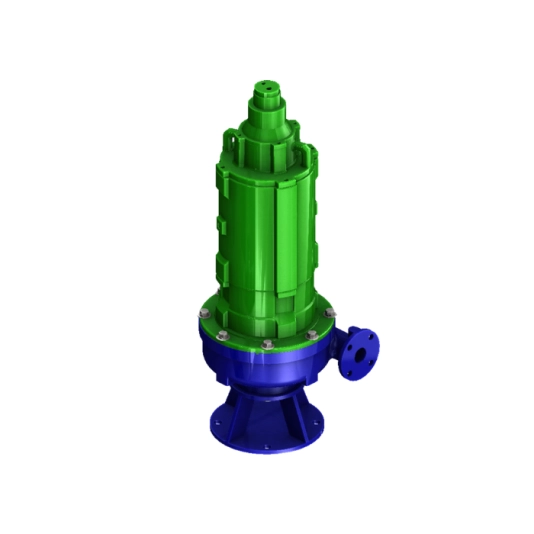

Discflo Submersible Pumps

Our submersible pumps often go to work where centrifugal, progressive cavity, lobe, and chopper pumps have failed. Their unique design and our state-of-the-art technology tackle even the toughest applications with ease.

Download

Produk Lainnya

Kennedy Hydraulic Nipple, 90°, M10x1.5, Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Kennedy Hydraulic Nipple, 90°, 1/8" BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Yamoto Side Lever Grease Gun, 500cc, Cartridge Fill

With a comfortable lever grip and offset nozzle, this chrome plated steel lever gun has a 500cc lever and is suited to 400g grease cartridges. Supplied with a flexible rubber hose and suited for medium to heavy greases.

Features and Benefits

• Includes a flexible rubber hose to allow you to begin working immediately

• Manufactured from steel for durability and resilience

• Rubber grip around the lever for comfort and grip when administering lubricants

Typical Applications

• Suited for controlled lubrication of medium and heavy greases to your desired work piece

Features and Benefits

• Includes a flexible rubber hose to allow you to begin working immediately

• Manufactured from steel for durability and resilience

• Rubber grip around the lever for comfort and grip when administering lubricants

Typical Applications

• Suited for controlled lubrication of medium and heavy greases to your desired work piece

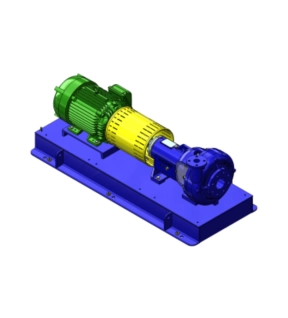

Discflo Horizontal Pumps

• No close tolerances

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations