Pump & Lubricants

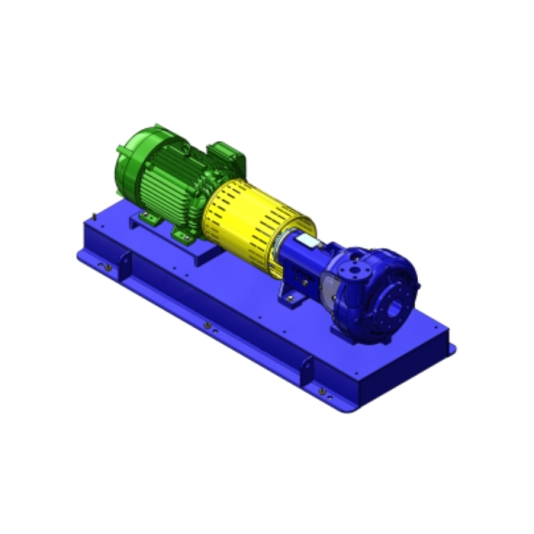

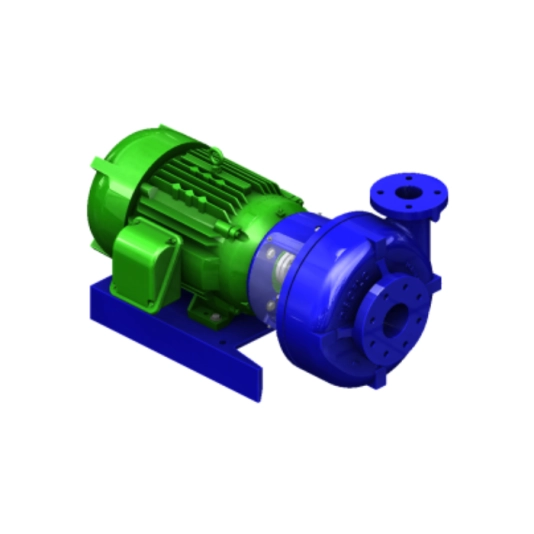

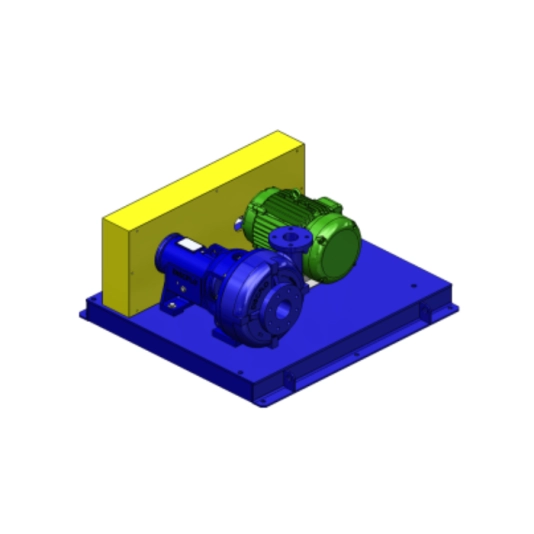

Discflo Horizontal Pumps

• No close tolerances

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations

Download

Produk Lainnya

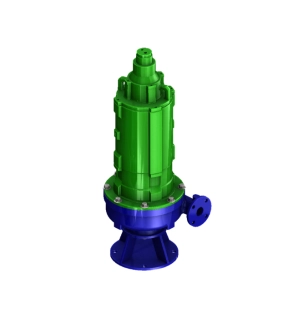

Discflo Submersible Pumps

Our submersible pumps often go to work where centrifugal, progressive cavity, lobe, and chopper pumps have failed. Their unique design and our state-of-the-art technology tackle even the toughest applications with ease.

Kennedy Oil Can, 1000cc, Metal

Comprising of an enamel finish and a heavy-gauge, seamless metal body, these oil cans are suited for heavy-duty applications. Each can has a positive force feed brass pump and valve and is supplied with both rigid metal and flexible nylon threaded spouts. Finished in a red colour.

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

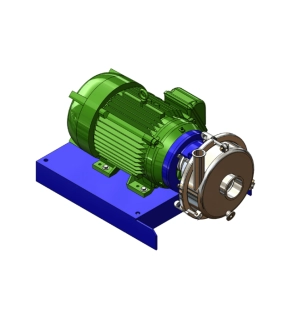

Discflo Sanitary Pumps

Discflo offers two lines of sanitary pumps, the SP Series and MIS Series. Both series meet 3-A sanitary and international hygiene standards and USDA requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

Kennedy Lever Pump, 0.3L

Suitable for lubricants, diesel and non-corrosive liquids, this lever pump is constructed from a zinc chrome finish steel and is completed with a telescopic suction tube. Suitable for container sizes 60 and 205 litres, the innlet on the pump is 2" BSP and M59 x 5 male thread.

Features and Benefits

• Manufactured from steel for durability

• Zinc chrome finish protects against corrosion and wear and tear

• Can be used with both 60 and 205 litre containers making it a versatile product

• Is compatible with non-corrosive liquids and most lubricants

• Telescopic suction tube allows you to adjust the tube to suit your desired container

Typical Applications

• Automotive

• Engineering

Features and Benefits

• Manufactured from steel for durability

• Zinc chrome finish protects against corrosion and wear and tear

• Can be used with both 60 and 205 litre containers making it a versatile product

• Is compatible with non-corrosive liquids and most lubricants

• Telescopic suction tube allows you to adjust the tube to suit your desired container

Typical Applications

• Automotive

• Engineering