Pump & Lubricants

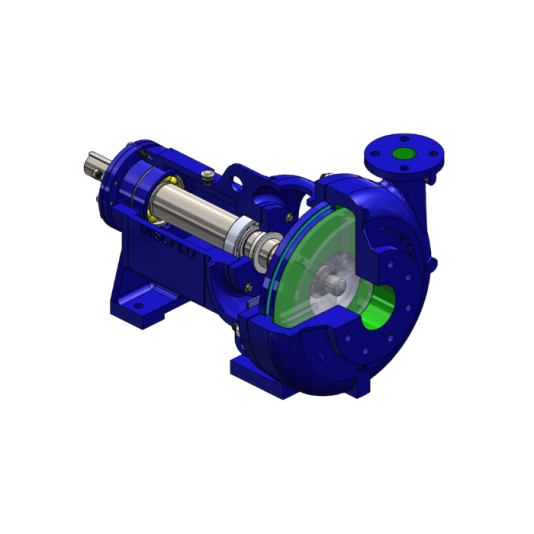

Discflo Glass Lined Pumps

Glass lining is a proven technique for adding a super-durable, smooth, non-stick surface to metal equipment and components.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Download

Produk Lainnya

Kennedy Hydraulic Nipple, Straight, M8x1.25, Steel

Available in three sizes, these metric straight type hydraulic grease nipples are suited for use with Kennedy® grease guns and all other hydraulic grease equipment.

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Kennedy Red-Hot-Dip Hot Dip, Bar, Translucent, 1 Pcs

Hot dip protective plastic coating moulds around the component or tool to provide 100% coverage and protect against impact and corrosion.

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot

Features and Benefits

• Hot dip plastic coating moulds itself around the part to provide 100% coverage and protect against corrosion and impacts for up to ten years

• Easy part identity through the translucent coating

• Simple to remove by peeling off

• Once removed, leaves behind a thin oil film to provide short term protection against corrosion

• Removed coatings may be reused saving cost

Notes

• Each single block measures (L)-150mm (H)-50mm (W)-80mm

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

Warnings

• Never directly apply heat to melt the protective dip

• Always use with a suitable melting pot

Kennedy Oil Can, 350cc, Metal

Comprising of an enamel finish and a heavy-gauge, seamless metal body, these oil cans are suited for heavy-duty applications. Each can has a positive force feed brass pump and valve and is supplied with both rigid metal and flexible nylon threaded spouts. Finished in a red colour.

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Kennedy SPS/205, Syphon Pump, 205L, Plastic

Available to suit 25 or 205 litre containers, these syphon pumps are an efficient way of controlling and dispensing a host of fluids. Comprised of a flexible plastic outlet and semi-rigid inlet tubes, the hand pumping units incorporate one-way valves. Suited for use with petrol and diesel as well as with non-corrosive liquids. All tubes can be cut to length and are fitted with a threaded bung. Model SPS/25 has a squeeze action and models SPS/205 and SPH/205 have a plunger-type action.

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive