Pump & Lubricants

Kennedy Hydraulic Nipple, Straight, M6x1, Steel

Available in three sizes, these metric straight type hydraulic grease nipples are suited for use with Kennedy® grease guns and all other hydraulic grease equipment.

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Features and Benefits

• Manufactured from steel for durability

• Available in three varying sizes to suit your specific applications

Typical Applications

• Engineering

• Fluid Handling

• Automotive

Download

Produk Lainnya

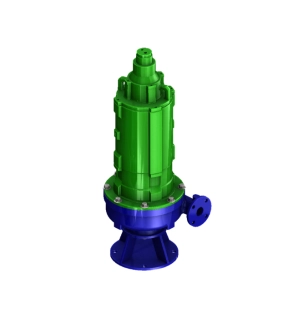

Discflo Submersible Pumps

Our submersible pumps often go to work where centrifugal, progressive cavity, lobe, and chopper pumps have failed. Their unique design and our state-of-the-art technology tackle even the toughest applications with ease.

Kennedy Side Lever Grease Gun, 500cc, Bulk/Cartridge/Suction Fill, 4500psi

These side lever grip grease guns are ideal for professional, extended use, with a sturdy chrome-plated steel body. They can be used with medium/heavy greases. The working pressure is 4500 psi/310 bar.

Features & Benefits

• Chrome-plated steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Typical Applications

• Applying lubricant to mechanical components

Notes

• Only LG400 has a rubber grip on the handle

Features & Benefits

• Chrome-plated steel body provides long lasting durability

• Side grip and offset nozzle allows precision on application

• Cartridge, bulk or suction fill allows for flexibility on refills

Typical Applications

• Applying lubricant to mechanical components

Notes

• Only LG400 has a rubber grip on the handle

Moresco Die Casting Lubricants

Die Realasing Fluids | GRAPHACE

Die casting is a casting method in which molten metals under high pressure are poured into molds and hardened. Our GRAPHACE series of die casting mold releasing lubricants is crucial for releasing heated metals from their molds. GRAPHACE brand die lubricants are used in die cast machines to cast aluminum, magnesium, and zinc parts, which results in better quality parts, improvements to plant productivity and a better working environment.

MS-1 White : liquid Excellent seizure resistance. Available for wide range of machine size at high dilution. Also available as anti-seize agent at low dilution.

GL-6300 Milky white : liquid It is a newly designed release agent considering the adhesion efficiency of release agent components.

Plunger Lubricants | NEOCASTER

During the die casting process, plunger lubricant is necessary to lubricate the sleeves and tips that force the molten metal into the molds. Our NEOCASTER brand plunger lubricant is used in the casting of aluminum parts for automobiles, motorcycles, mobile phones, and similar objects. Using the NEOCASTER plunger lubricant has proven to increase the life of the tip and the shot sleeve as well as improve the casting quality.

PWS-850 : Yellowish brown Good wettability to the metal surface. Stable lubricity at high temperature.

PW-50 : Milky white liquid Available for small and midium-sized machine.

B-200R : Black General purpose type.

RE-77 : Milky white liquid Suitable for small and medium-sized machine.

Die casting is a casting method in which molten metals under high pressure are poured into molds and hardened. Our GRAPHACE series of die casting mold releasing lubricants is crucial for releasing heated metals from their molds. GRAPHACE brand die lubricants are used in die cast machines to cast aluminum, magnesium, and zinc parts, which results in better quality parts, improvements to plant productivity and a better working environment.

MS-1 White : liquid Excellent seizure resistance. Available for wide range of machine size at high dilution. Also available as anti-seize agent at low dilution.

GL-6300 Milky white : liquid It is a newly designed release agent considering the adhesion efficiency of release agent components.

Plunger Lubricants | NEOCASTER

During the die casting process, plunger lubricant is necessary to lubricate the sleeves and tips that force the molten metal into the molds. Our NEOCASTER brand plunger lubricant is used in the casting of aluminum parts for automobiles, motorcycles, mobile phones, and similar objects. Using the NEOCASTER plunger lubricant has proven to increase the life of the tip and the shot sleeve as well as improve the casting quality.

PWS-850 : Yellowish brown Good wettability to the metal surface. Stable lubricity at high temperature.

PW-50 : Milky white liquid Available for small and midium-sized machine.

B-200R : Black General purpose type.

RE-77 : Milky white liquid Suitable for small and medium-sized machine.

Kennedy Hydraulic Nipple, 45°, 1/8"x28 BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.