Pump & Lubricants

Kennedy Hydraulic Nipple, 90°, M8x1.25, Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Download

Produk Lainnya

Kennedy Hydraulic Nipple, 45°, M6x1, Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

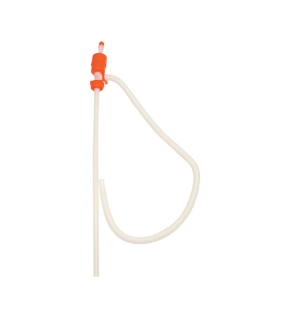

Kennedy SPH/205, Syphon Pump, 205L, Plastic

Available to suit 25 or 205 litre containers, these syphon pumps are an efficient way of controlling and dispensing a host of fluids. Comprised of a flexible plastic outlet and semi-rigid inlet tubes, the hand pumping units incorporate one-way valves. Suited for use with petrol and diesel as well as with non-corrosive liquids. All tubes can be cut to length and are fitted with a threaded bung. Model SPS/25 has a squeeze action and models SPS/205 and SPH/205 have a plunger-type action.

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

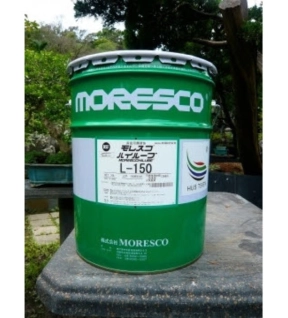

Moresco High Temperature Lubricants

HILUBE

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

Kennedy Oil Can, 500cc, Metal

Comprising of an enamel finish and a heavy-gauge, seamless metal body, these oil cans are suited for heavy-duty applications. Each can has a positive force feed brass pump and valve and is supplied with both rigid metal and flexible nylon threaded spouts. Finished in a red colour.

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction