Measuring Tools

Fluke Termometer IR Fluke 64 MAX

The Fluke 64 MAX thermometer has the precision you need to do the job accurately and won't exceed your budget. Designed and tested to withstand a drop of 3 meters, you can count on this compact and lightweight infrared thermometer to work when you need it in the harshest environments and when you can't get near it.

Download

Produk Lainnya

Fluke VT08 Visual IR Termometer

The Fluke VT Series is built with legendary Fluke toughness and quality. With a compact design and enhanced functionality, temperature measurements are visualized, so you can obtain clear and accurate infrared thermal images.

Fluke 715 Volt/mA Loop Calibrator

The Fluke 715 Volt/ mA Calibrator provides outstanding performance, durability and reliability. Offered in the rugged Fluke 80 Series DMM package, the calibrator is compact, lightweight and easy to transport. With a push button interface similar to the multifunctional Fluke 740 Series Documenting , the 715 is easy to use. It is EMI, dust, splash proof and has a removable battery cover for quick battery changes.

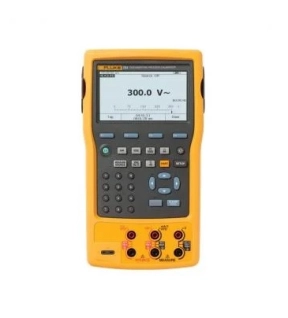

Fluke 754 Documenting Process Calibrator-HART

Portable multi-function calibrator simplifies calibration work

Whether you're calibrating instruments, troubleshooting a problem, or running routine maintenance, the Fluke 754 with HART® communication can help you get the job done faster. It does many different tasks quickly and it's the only process calibrator you need to carry. This rugged, reliable, integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART smart transmitters and other instrumentation.

Measurement and source capabilities:

- AC/DC voltage

- mA loop w/ 24V loop power

- Pressure

- Thermocouples & RTDs

- Frequency

- Resistance

Enhanced process calibrator operation

With the bright white dual display, you’ll be able to read both sourced and measured parameters simultaneously. The rechargeable Li-Ion battery offers up to 10 hours uninterrupted usage allowing you to complete one task after another without needing to stop, and also includes direct AC power capabilities if needed. Finally, communicate with HART smart digital transmitters directly through the mA measurement jacks for seamless calibration with fewer connections.

Do more, with less

The 754 does the work of several tools. It sources, simulates and measures pressure, temperature, and electrical signals with one rugged, hand-held device. The powerful built-in HART interface can perform nearly all day-to-day tasks you now perform with a separate digital communicator. It can handle fast-pulsed RTD transmitters and PLCs, with pulses as short as 1 ms. The 754 also measures/sources pressure using any of the Fluke 750P Series Pressure Modules as a reference and boasts many additional features like:

- Custom auto-step and ramping

- Custom units

- User-entered values during test

- One-point and two-point switch testing

- Square root DP flow testing

- Programmable measurement delay

Download procedures, lists, and instructions

The 754 is a power multifunction documenting calibrator that you can use to download procedures, lists, and instructions created with software, or upload data for printing, archiving, and analysis. The tool can hold up to a full week of downloaded procedures and calibration results and offers compatibility with many asset management software. Users can also create and run automated as-found or as-left procedures to satisfy quality programs or regulations, and records and documents results.

For documentation, the 754 automates calibration procedures and captures your data. And, of course, it helps you meet rigorous standards like ISO 9000, FDA, EPA, and OSHA regulations. Plus, the graphical screen, Li-Ion battery for longer life, USB port, and accessories help you work smarter and faster.

To create a seamless/paperless calibration management system consider adding Fluke DPCTrack2 Calibration Management software.

Whether you're calibrating instruments, troubleshooting a problem, or running routine maintenance, the Fluke 754 with HART® communication can help you get the job done faster. It does many different tasks quickly and it's the only process calibrator you need to carry. This rugged, reliable, integrated communicating calibrator is ideal for calibrating, maintaining, and troubleshooting HART smart transmitters and other instrumentation.

Measurement and source capabilities:

- AC/DC voltage

- mA loop w/ 24V loop power

- Pressure

- Thermocouples & RTDs

- Frequency

- Resistance

Enhanced process calibrator operation

With the bright white dual display, you’ll be able to read both sourced and measured parameters simultaneously. The rechargeable Li-Ion battery offers up to 10 hours uninterrupted usage allowing you to complete one task after another without needing to stop, and also includes direct AC power capabilities if needed. Finally, communicate with HART smart digital transmitters directly through the mA measurement jacks for seamless calibration with fewer connections.

Do more, with less

The 754 does the work of several tools. It sources, simulates and measures pressure, temperature, and electrical signals with one rugged, hand-held device. The powerful built-in HART interface can perform nearly all day-to-day tasks you now perform with a separate digital communicator. It can handle fast-pulsed RTD transmitters and PLCs, with pulses as short as 1 ms. The 754 also measures/sources pressure using any of the Fluke 750P Series Pressure Modules as a reference and boasts many additional features like:

- Custom auto-step and ramping

- Custom units

- User-entered values during test

- One-point and two-point switch testing

- Square root DP flow testing

- Programmable measurement delay

Download procedures, lists, and instructions

The 754 is a power multifunction documenting calibrator that you can use to download procedures, lists, and instructions created with software, or upload data for printing, archiving, and analysis. The tool can hold up to a full week of downloaded procedures and calibration results and offers compatibility with many asset management software. Users can also create and run automated as-found or as-left procedures to satisfy quality programs or regulations, and records and documents results.

For documentation, the 754 automates calibration procedures and captures your data. And, of course, it helps you meet rigorous standards like ISO 9000, FDA, EPA, and OSHA regulations. Plus, the graphical screen, Li-Ion battery for longer life, USB port, and accessories help you work smarter and faster.

To create a seamless/paperless calibration management system consider adding Fluke DPCTrack2 Calibration Management software.

Fluke 566 Thermal Gun Infrared & Contact Thermometer

The 566 IR and contact thermometer features a simple, three-button, on-screen menu interface (in 6 languages) to make it easier than ever to measure temperature. You can quickly navigate advanced features to adjust emissivity, start data logging, or turn alarms on and off with just a few pushes of a button. And with its rugged, easy-to-use, ergonomic design, the Fluke 566 can stand up to tough industrial, electrical, and mechanical environments. These tools go beyond other IR thermometers (or pyrometers), helping you work more efficiently in more applications.

Other useful features:

- Adjustable emissivity that allows you to confidently measure a wide variety of surfaces

- Up to 20 points of data for downloading and recalling later

- Two levels of backlight on the display

- Included Type-K thermocouple bead probe

- Features audible and visual alarms to instantly alert you to measurements outside of your set limits

- Provides MAX, MIN, DIF and AVG functions to quickly identify problems

Other useful features:

- Adjustable emissivity that allows you to confidently measure a wide variety of surfaces

- Up to 20 points of data for downloading and recalling later

- Two levels of backlight on the display

- Included Type-K thermocouple bead probe

- Features audible and visual alarms to instantly alert you to measurements outside of your set limits

- Provides MAX, MIN, DIF and AVG functions to quickly identify problems