Measuring Tools

Kennedy 150mm/6" FLEXIBLE RUSTLES S RULE ROUND END

The range of Kennedy round end engineers rulers are made from spring tempered flexible steel blades with permanent black figures and graduations. With rustless properties and 12mm blade width and and a satin chrome anti-glare finish they are extremly easy to read with EEC Class one accuracy (/- 0.2mm full scale). Features a handy hanging hole for easy storage.

Features and Benefits

• Spring tempered flexible steel blades with round end

• Anti-glare properties

• With hanging hole for easy storage

• Permanent black figures and graduations

• ECC Class one accuracy

Typical Applications

• Measurements

• Engineering

• Industrial

• Workshop

• On site

Notes

• Available in imperial and metric measurements

Features and Benefits

• Spring tempered flexible steel blades with round end

• Anti-glare properties

• With hanging hole for easy storage

• Permanent black figures and graduations

• ECC Class one accuracy

Typical Applications

• Measurements

• Engineering

• Industrial

• Workshop

• On site

Notes

• Available in imperial and metric measurements

Download

Produk Lainnya

Fluke Fluke ii500 Acoustic Imager

Fluke ii500 Acoustic Imager with LeakQ™: Detect, Locate, and Capture Gas Leaks

The Fluke ii500 Acoustic Imager, equipped with LeakQ™ technology, empowers maintenance teams to detect and locate gas leaks efficiently. Designed for ease of use, it requires no specialized training. Even during peak production periods, teams can effectively identify gas and vacuum leaks. The ii500's advanced acoustic leak detection technology isolates leak sound frequencies, making leaks visible even in noisy environments.

Key features

• Ready-to-Use: The Fluke ii500 is ready out of the box. Its rugged, ergonomic design ensures easy handling, while the large 7" LCD display allows for clear leak visualization.

• Quick Detection: Even users with minimal experience can start detecting leaks within minutes. The tool estimates relative leak size and cost, incorporating a new distance-estimation feature and the 1-10 LeakQ™ severity index.

• SoundMap™ Overlay: The 7" LCD touchscreen overlays a SoundMap™ on visual images, facilitating rapid leak location identification.

• Intuitive Interface: Easily isolate leak sound frequencies and filter out background noise.

• Tagging and Organization: Use image and video tagging, annotation, and folders for efficient organization.

• Leak Sizing: Prioritize repairs based on relative leak size.

• Collaboration: The reporting tool allows sharing of visuals, tagging, and notes with team members and repair personnel.

The Fluke ii500 Acoustic Imager, equipped with LeakQ™ technology, empowers maintenance teams to detect and locate gas leaks efficiently. Designed for ease of use, it requires no specialized training. Even during peak production periods, teams can effectively identify gas and vacuum leaks. The ii500's advanced acoustic leak detection technology isolates leak sound frequencies, making leaks visible even in noisy environments.

Key features

• Ready-to-Use: The Fluke ii500 is ready out of the box. Its rugged, ergonomic design ensures easy handling, while the large 7" LCD display allows for clear leak visualization.

• Quick Detection: Even users with minimal experience can start detecting leaks within minutes. The tool estimates relative leak size and cost, incorporating a new distance-estimation feature and the 1-10 LeakQ™ severity index.

• SoundMap™ Overlay: The 7" LCD touchscreen overlays a SoundMap™ on visual images, facilitating rapid leak location identification.

• Intuitive Interface: Easily isolate leak sound frequencies and filter out background noise.

• Tagging and Organization: Use image and video tagging, annotation, and folders for efficient organization.

• Leak Sizing: Prioritize repairs based on relative leak size.

• Collaboration: The reporting tool allows sharing of visuals, tagging, and notes with team members and repair personnel.

Fluke RSE600 Mounted Infrared Camera

When it's not just infrared.

Introducing Fluke infrared cameras, the first with full radiometry technology – the RSE series. Packed with advanced features and plug-in software for MATLAB® and LabVIEW® , these tools are ideal for continuous streaming and analysis of infrared data.

Designed for your research, science and engineering needs, enhance your testing and quality assurance procedures by attaching the RSE600 to your workstation. Continuously stream up to 60 frames per second of data directly to your computer to monitor minute temperature differences, as well as analyze remote video frame-by-frame from the SmartView® desktop software . Get an even more perfect screen with add-on lenses to target different applications (analyzing from a distance, or getting detailed close-ups).

Don't just look at the heat. Stream, measure and analyze its power as well.

With plug-ins for MATLAB® and LabVIEW® , the RSE Infrared Camera is perfect for testing and development. Looking for more robust software to monitor and archive processing manufacturing data 24/7? We recommend the ThermoView® series from Fluke Process Instruments. Check out a quick comparison

Introducing Fluke infrared cameras, the first with full radiometry technology – the RSE series. Packed with advanced features and plug-in software for MATLAB® and LabVIEW® , these tools are ideal for continuous streaming and analysis of infrared data.

Designed for your research, science and engineering needs, enhance your testing and quality assurance procedures by attaching the RSE600 to your workstation. Continuously stream up to 60 frames per second of data directly to your computer to monitor minute temperature differences, as well as analyze remote video frame-by-frame from the SmartView® desktop software . Get an even more perfect screen with add-on lenses to target different applications (analyzing from a distance, or getting detailed close-ups).

Don't just look at the heat. Stream, measure and analyze its power as well.

With plug-ins for MATLAB® and LabVIEW® , the RSE Infrared Camera is perfect for testing and development. Looking for more robust software to monitor and archive processing manufacturing data 24/7? We recommend the ThermoView® series from Fluke Process Instruments. Check out a quick comparison

Fluke 715 Volt/mA Loop Calibrator

The Fluke 715 Volt/ mA Calibrator provides outstanding performance, durability and reliability. Offered in the rugged Fluke 80 Series DMM package, the calibrator is compact, lightweight and easy to transport. With a push button interface similar to the multifunctional Fluke 740 Series Documenting , the 715 is easy to use. It is EMI, dust, splash proof and has a removable battery cover for quick battery changes.

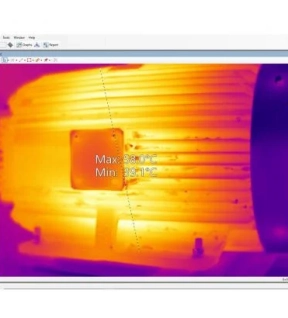

Fluke SmartView R&D Thermal Imaging Software

- Customizable reports - display the information you need based on your application

- Real time radiometric data streaming capability

- Data trending and time plots

- Advanced analysis features; Spot measures, lines/profiles, area/histograms, hot/cold markers, rulers, adjustable emmisivity by object, and more

- Easy to use file management

- Real time radiometric data streaming capability

- Data trending and time plots

- Advanced analysis features; Spot measures, lines/profiles, area/histograms, hot/cold markers, rulers, adjustable emmisivity by object, and more

- Easy to use file management