Cutting Tools

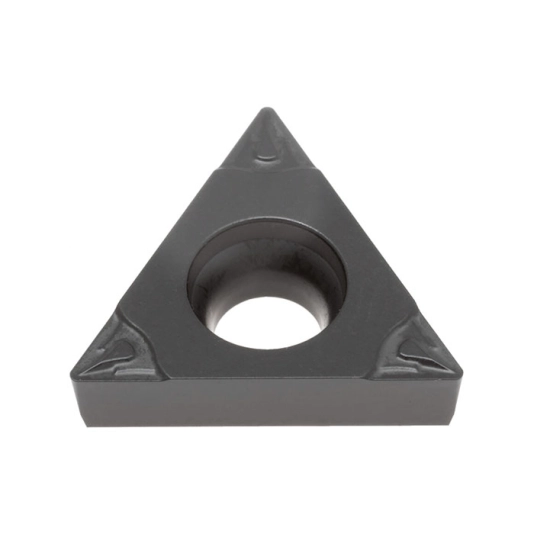

Yamaloy TCGT 16T304-PF, Turning Insert, Grade QX5020, Carbide, Triangle

TCGT turning inserts feature a CVD coated substrate providing an excellent general purpose grade for medium roughing on steels, stainless and cast irons.

Features and Benefits

• CVD MT-TiCN-Al2O3-TiN coating for increased heat and wear resistance

• Tough substrate for increased cutting strength

• Versatile usage can be used in a range of applications from roughing to finishing

• PF chipbreaker for good chip flow

Typical Applications

• General purpose

• Medium roughing

• Finishing

• Steel

• Stainless steel

• Cast iron

Finish.

Standards

• Insert Grade QX5020

• (ISO P10-P35 M10-M30 K10-K30)

Features and Benefits

• CVD MT-TiCN-Al2O3-TiN coating for increased heat and wear resistance

• Tough substrate for increased cutting strength

• Versatile usage can be used in a range of applications from roughing to finishing

• PF chipbreaker for good chip flow

Typical Applications

• General purpose

• Medium roughing

• Finishing

• Steel

• Stainless steel

• Cast iron

Finish.

Standards

• Insert Grade QX5020

• (ISO P10-P35 M10-M30 K10-K30)

Download

Produk Lainnya

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 9.5mm, Conical

Cut 6 carbide rotary burrs feature a crosscut and double cut to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use.

Features and Benefits

• Manufactured from carbide for greater hardness

• Cut 6 crosscut and double cut to improve control and chipbreaks

• Suitable for use on hard materials up to HRC65 hardness

Typical Applications

• Deburring

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

Notes

• Work piece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

Cut 6 - Double Cut.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Features and Benefits

• Manufactured from carbide for greater hardness

• Cut 6 crosscut and double cut to improve control and chipbreaks

• Suitable for use on hard materials up to HRC65 hardness

Typical Applications

• Deburring

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

Notes

• Work piece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

Cut 6 - Double Cut.

Cut 9 - Chipbreaker

Chipbreaker fast stock removal for improved control and reduced chips for use on hard materials, i.e. steel alloy 50RC, 60RC, carbon and cast iron.

Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel etc.

up to HRC65 hardness.

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Kennedy Carbide Burr, Uncoated, Chipbreaker, 8.0mm, Cylindrical End Cut

These carbide burrs are designed for cylindrical end cutting of low feed, high speed materials. Available in a variety of sizes with varying cut capabilities.

Features and Benefits

• Manufactured from durable carbide for tool longevity

• Rapid cut (Cut 3) burrs are suited for use on softer non-ferrous and plastic materials

• Chipbreaker (Cut 9) burrs are suited for use on cast iron, carbon steel, alloy steel 50RC and 60RC

• Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel up to HRC65 hardness

• Ideal for light stock removal at high rpms

Typical Applications

• Deburring

Notes

• Not suitable for milling large amounts of material

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

Features and Benefits

• Manufactured from durable carbide for tool longevity

• Rapid cut (Cut 3) burrs are suited for use on softer non-ferrous and plastic materials

• Chipbreaker (Cut 9) burrs are suited for use on cast iron, carbon steel, alloy steel 50RC and 60RC

• Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel up to HRC65 hardness

• Ideal for light stock removal at high rpms

Typical Applications

• Deburring

Notes

• Not suitable for milling large amounts of material

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used

• Always ensure that the tool is rated to the recommended operating speed of the burr

Sherwood Step Drill, 4 to 39, High Speed Steel

HSS multi diameter step drills produce good quality holes in a wide variety of sheet metal, using either a bench drill or light pedestal drilling machine. Manufactured from high speed steel, they offer sound rigidity, strength and stability when machining. Each tool cuts parallel holes in a range of specific sizes and is compatible with materials up to 1/8" (3mm) thick.

Features and Benefits

• High speed steel construction for greater strength, rigidity and stability

• Excellent wear and heat resistance for prolonged tool life

• Cuts parallel holes in sheet metal

Typical Applications

• Drilling

• Sheet metal

Notes

• Available sizes 1-12mm to 6-37mm

Features and Benefits

• High speed steel construction for greater strength, rigidity and stability

• Excellent wear and heat resistance for prolonged tool life

• Cuts parallel holes in sheet metal

Typical Applications

• Drilling

• Sheet metal

Notes

• Available sizes 1-12mm to 6-37mm

Sherwood Jobber Drill, 14mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN