Cutting Tools

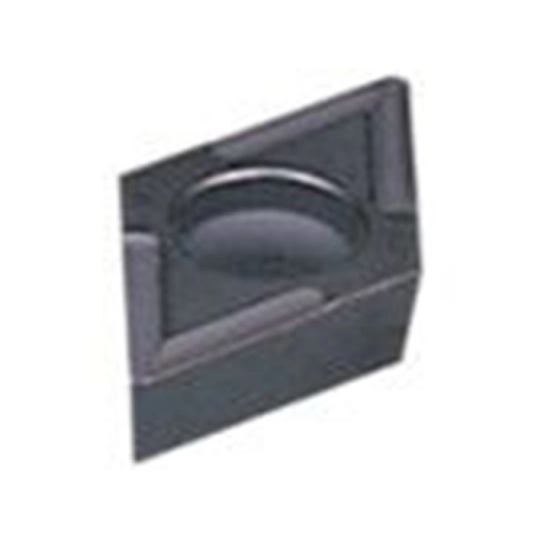

Yamaloy DCMT 11T304-PM, Turning Insert, Grade QX5030, Carbide, 55° Rhombic

DCMT Turning Inserts

55° Rhombic Insert

Insert Grades QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: PM. Application: Med Cut.

55° Rhombic Insert

Insert Grades QX5030

(ISO P20-P40 M20-M30) CVD Coated. - Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

Chip Breaker: PM. Application: Med Cut.

Download

Produk Lainnya

Sherwood Jobber Drill, 13.5mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Sherwood Counterbore, 18mm, High Speed Steel, 3 fl, Plain Shank, Uncoated

Plain Shank

Spiral flute, 3 flute. Medium duty. Used for milling of pre-drilled holes to allow bolt or cap head screws to lie flush with the component surface. Manufactured to manufacturers standard

Spiral flute, 3 flute. Medium duty. Used for milling of pre-drilled holes to allow bolt or cap head screws to lie flush with the component surface. Manufactured to manufacturers standard

Kennedy Masonry Drill Bit, 6mm x 150mm, Straight

Tungsten carbide tipped with roll forged flutes.

Features and Benefits

• Hard tungsten carbide tips for clean and accurate holes

• Universal compatibility - fits most tools

• Shank type: Straight

• Flute construction: Roll forged

Typical Applications

• A general purpose mortar and masonry drill bit suitable for workshop and maintenance

Standards

• Manufactured to DIN 8039

Features and Benefits

• Hard tungsten carbide tips for clean and accurate holes

• Universal compatibility - fits most tools

• Shank type: Straight

• Flute construction: Roll forged

Typical Applications

• A general purpose mortar and masonry drill bit suitable for workshop and maintenance

Standards

• Manufactured to DIN 8039

Senator Tap & Die Set, M3 - M12, Metric, Set of 32

A comprehensive threading set containing machine ground metric Taps and Dies made from durable high speed steel. Supplied in a metal carry case the set allows for easy storage and portability.

Features and Benefits

• A comprehensive set of machine ground HSS taps and dies

• Manufactured from high speed steel for rigidity

• Ideal for general workshop and maintenance use*

• Supplied packaged in a metal carry case

Contents

• Carbon Steel Dies: from M3 to M12

• Ground Thread Taps (taper, second and plug lead): from M3 to M12

• Bar Type Tap Wrench: M1 - M12 x 210mm

• Die Stock: 25 x 9 x 210mm

• Metric Thread Pitch Gauge

• Flat Bladed Screwdriver: 6mm

Standards

• Conforms to ISO529 and BS1127

Typical Applications

• Threading

• Tapping

• Workshop

Notes

• For general workshop and maintenance use only*

Features and Benefits

• A comprehensive set of machine ground HSS taps and dies

• Manufactured from high speed steel for rigidity

• Ideal for general workshop and maintenance use*

• Supplied packaged in a metal carry case

Contents

• Carbon Steel Dies: from M3 to M12

• Ground Thread Taps (taper, second and plug lead): from M3 to M12

• Bar Type Tap Wrench: M1 - M12 x 210mm

• Die Stock: 25 x 9 x 210mm

• Metric Thread Pitch Gauge

• Flat Bladed Screwdriver: 6mm

Standards

• Conforms to ISO529 and BS1127

Typical Applications

• Threading

• Tapping

• Workshop

Notes

• For general workshop and maintenance use only*