Cutting Tools

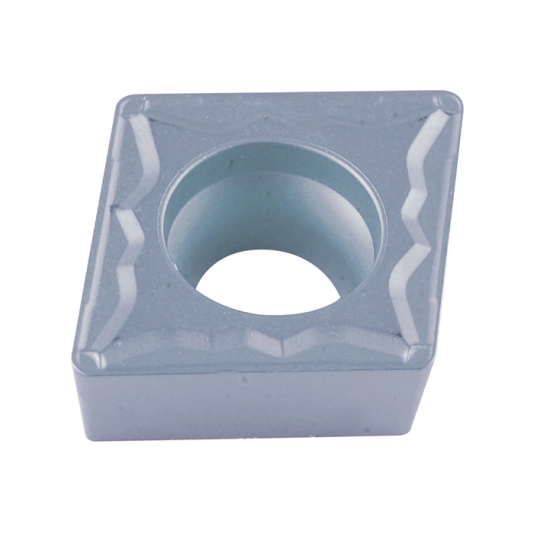

Yamaloy CCMT 09T308-PM, Turning Insert, Grade QX5020, Carbide, 80° Rhombic

CCMT Turning Inserts

80° Rhombic Insert

Insert Grade QX5020

(ISO P10-P35 M10-M30 K10-K30) CVD Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

80° Rhombic Insert

Insert Grade QX5020

(ISO P10-P35 M10-M30 K10-K30) CVD Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Download

Produk Lainnya

Sherwood Jobber Drill, 5mm, Normal Helix, High Speed Steel, Bright

Series J100 - Metric general purpose drills for steels, cast steel, grey cast iron, malleable cast iron, nickel brass, aluminium alloy and graphite.

Features and Benefits

• High speed steel construction with bright finish for increased toughness

• Supplied in the as-ground condition for use with non ferrous materials

Standards

• Manufactured to BS 328/DIN338RN

Notes

• Drills with a bright finish are supplied in the as-ground condition and such tools are used generally in the machining of non-ferrous materials.

Features and Benefits

• High speed steel construction with bright finish for increased toughness

• Supplied in the as-ground condition for use with non ferrous materials

Standards

• Manufactured to BS 328/DIN338RN

Notes

• Drills with a bright finish are supplied in the as-ground condition and such tools are used generally in the machining of non-ferrous materials.

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 3mm, Ball Nosed Cylindrical

Cut 6 cylindrical ball nosed rotary burrs feature crosscut and double cut profile to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use. Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel, up to HRC65 hardness.

Features and Benefits

• Tungsten carbide construction for improved hardness and strength

• Crosscut and double cut profile to improve and control chipbreaks

Typical Applications

• Deburring

• Steel

• Cast iron

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Additional

• Image for illustration purposes only

Features and Benefits

• Tungsten carbide construction for improved hardness and strength

• Crosscut and double cut profile to improve and control chipbreaks

Typical Applications

• Deburring

• Steel

• Cast iron

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Additional

• Image for illustration purposes only

Sherwood Hand Tap Set , M5 x 0.8mm, Metric Coarse, High Speed Steel, Bright, Set of 3

A set of three Sherwood HSS Taps ideal for the general purpose option for thread cutting in most materials including steel, some stainless steels, cast irons and non-ferrous materials such as Aluminium, Brass and many others.

Features and Benefits

• Manufactured from durable high speed steel

• Precision ground flutes for accurate thread cutting

• Features class 2 thread forms with medium fit tolerance

• Manufactured with a bright finish

Typical Applications

• Tapping

• Steel

• Brass

• Aluminium

• Engineering

• Manufacturing

Standards

• Tap dimensions to ISO529

• Thread Forms are Class 2 medium fit tolerance

• Straight Flute Individual Sizes IS0 529

Notes

• Available in sizes 1.0 x 0.25mm - 48 x 5.00mm

• Set of 3 - 1 Taper, second and plug

Features and Benefits

• Manufactured from durable high speed steel

• Precision ground flutes for accurate thread cutting

• Features class 2 thread forms with medium fit tolerance

• Manufactured with a bright finish

Typical Applications

• Tapping

• Steel

• Brass

• Aluminium

• Engineering

• Manufacturing

Standards

• Tap dimensions to ISO529

• Thread Forms are Class 2 medium fit tolerance

• Straight Flute Individual Sizes IS0 529

Notes

• Available in sizes 1.0 x 0.25mm - 48 x 5.00mm

• Set of 3 - 1 Taper, second and plug

Kennedy Carbide Burr, Uncoated, Chipbreaker, 3.0mm, Conical

Cut 9 conical carbide burrs feature a cut-9 chipbreaker for fast stock removal, improved control and reduced chips. Ideally suited to hard materials such as steel alloy 50RC, 60RC, carbon and cast iron.

Features and Benefits

• Manufactured from a tough carbide substrate for greater tool hardness

• Cut-9 chipbreaker increases stock removal and chip control

• Ideal for use on hard materials such as steel alloys and more

Typical Applications

• Deburring

• Polishing

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

• Materials up to HRC65 hardness

Notes

• Workpiece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal at high rpm's 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Features and Benefits

• Manufactured from a tough carbide substrate for greater tool hardness

• Cut-9 chipbreaker increases stock removal and chip control

• Ideal for use on hard materials such as steel alloys and more

Typical Applications

• Deburring

• Polishing

• Cast iron

• Cast steel

• Carbon steel

• Alloy steel

• Stainless steel

• Materials up to HRC65 hardness

Notes

• Workpiece and tools should always be steady and well supported

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal at high rpm's 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.