Cutting Tools

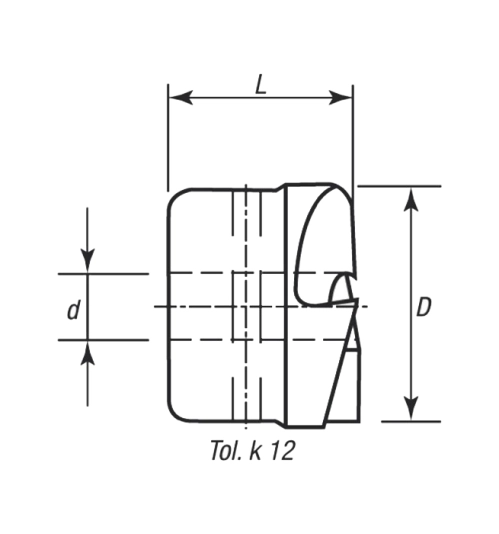

Granlund Backspotfacing Tool, U, 25mm, U-09/25, High Speed Steel, Bright

U-09

Download

Produk Lainnya

Kennedy Countersink, 2.0 - 5.0mm, Straight Shank, 1 fl, 90°, Cobalt High Speed Steel

Manufactured from M35 HSS and used for the deburring and chamfering of most metals and plastics. Features straight shanks and manufactured to BS 328 : Part 5 : 1983.

• Single hole head with nclusive angle of 90° for excellent cutting performance

• Manufactured from M35 HSS for increased toughness

• Uncoated with good heat and wear resistance

Typical Applications

•Countersinking

Standards

• Manufactured to BS 328 : Part 5 : 1983

• Single hole head with nclusive angle of 90° for excellent cutting performance

• Manufactured from M35 HSS for increased toughness

• Uncoated with good heat and wear resistance

Typical Applications

•Countersinking

Standards

• Manufactured to BS 328 : Part 5 : 1983

York Carbide Burr, Uncoated, Cut 6 - Double Cut, 8mm, Ball Nosed Cylindrical

Cut 6 cylindrical ball nosed rotary burrs feature crosscut and double cut profile to improve control and chipbreaks. Manufactured from high grade tungsten carbide for general-purpose use. Suitable for deburring and polishing of cast iron, cast steel, carbon steel, alloy steel and stainless steel, up to HRC65 hardness.

Features and Benefits

• Tungsten carbide construction for improved hardness and strength

• Crosscut and double cut profile to improve and control chipbreaks

Typical Applications

• Deburring

• Steel

• Cast iron

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Additional

• Image for illustration purposes only

Features and Benefits

• Tungsten carbide construction for improved hardness and strength

• Crosscut and double cut profile to improve and control chipbreaks

Typical Applications

• Deburring

• Steel

• Cast iron

Please note:

• Work piece and tools should always be steady and well supported.

• Carbide burrs are not suitable for 'milling' large amounts of material, they are for light stock removal and high revolutions 'LOW FEED - HIGH SPEED'.

• Always ensure that at least 70% of the shank length is clamped by the collet or chuck of the tool being used.

• Always ensure that the tool is rated to the recommended operating speed of the burr.

Additional

• Image for illustration purposes only

Sherwood Hand Tap Set , M10 x 1.5mm, Metric Coarse, High Speed Steel, Bright, Set of 3

A set of three Sherwood HSS Taps ideal for the general purpose option for thread cutting in most materials including steel, some stainless steels, cast irons and non-ferrous materials such as Aluminium, Brass and many others.

Features and Benefits

• Manufactured from durable high speed steel

• Precision ground flutes for accurate thread cutting

• Features class 2 thread forms with medium fit tolerance

• Manufactured with a bright finish

Typical Applications

• Tapping

• Steel

• Brass

• Aluminium

• Engineering

• Manufacturing

Standards

• Tap dimensions to ISO529

• Thread Forms are Class 2 medium fit tolerance

• Straight Flute Individual Sizes IS0 529

Notes

• Available in sizes 1.0 x 0.25mm - 48 x 5.00mm

• Set of 3 - 1 Taper, second and plug

Features and Benefits

• Manufactured from durable high speed steel

• Precision ground flutes for accurate thread cutting

• Features class 2 thread forms with medium fit tolerance

• Manufactured with a bright finish

Typical Applications

• Tapping

• Steel

• Brass

• Aluminium

• Engineering

• Manufacturing

Standards

• Tap dimensions to ISO529

• Thread Forms are Class 2 medium fit tolerance

• Straight Flute Individual Sizes IS0 529

Notes

• Available in sizes 1.0 x 0.25mm - 48 x 5.00mm

• Set of 3 - 1 Taper, second and plug

Kennedy Bi-Metal High Speed Steel, Saw Blade, For Hacksaw, 300mm, Pack of 1

Combining shatter resistant spring steel, used as the backing material, and tough, wear-resistant HSS teeth, this range of replacement hacksaw blades are the ideal product for replacing your blunt or old hacksaw blades. Electron-beam welded to form a sturdy bi-metal product, the product is well suited for making interrupted cuts in cramped places or places where the blade is subject to stress caused by twisting or bending. Provides optimum tooth strength/life and reduced breakage and fracture when compared to traditional all-hard blades. Hacksaw body not included, blades only provided.

Features and Benefits

• HSS (High Speed Steel) cuts faster than high carbon steels and maintains hardness for longer than carbon steels

• Possesses a flexible spring steel backing to allow for sawing in hard to reach or awkward areas

• The differing materials have been electron-beam welded together for a neat join and sturdy product finish

• Available to purchase individually

Typical Applications

• Ideal for use in awkward or hard to reach areas due to its high tolerance of twisting and bending

• Suited for use as replacement blades for a standard hacksaw

Standards

• Made to BS 1919 : Part 1: 1993

Features and Benefits

• HSS (High Speed Steel) cuts faster than high carbon steels and maintains hardness for longer than carbon steels

• Possesses a flexible spring steel backing to allow for sawing in hard to reach or awkward areas

• The differing materials have been electron-beam welded together for a neat join and sturdy product finish

• Available to purchase individually

Typical Applications

• Ideal for use in awkward or hard to reach areas due to its high tolerance of twisting and bending

• Suited for use as replacement blades for a standard hacksaw

Standards

• Made to BS 1919 : Part 1: 1993