Cutting Tools

Kennedy 250mm, Self Grip Pliers, Jaw Straight

Comprised of a rolled chrome vanadium steel body, with drop-forged hardened steel jaws with corrosion-resistant bright nickel coating, these grip wrenches are ideally suited for heavy duty applications. The dual material handle design allows the user to apply the greatest force with the minimum amount of effort, whilst the jaw opening and clamping pressure can be adjusted with the knurled head screw. Each product is fitted with wire spring to ensure efficient opening of the jaws. The locking mechanism holds the wrench in place once adjusted, leaving both hands free. Available in two sizes.

Features and Benefits

• Heavy duty rolled chrome vanadium steel construction makes for a durable product

• Comfort grip improves user grip, comfort and control when using

• Locks securely in place to allow for a hands free operation

• Quick release lever allows you to easily disengage the tool

• Drop forged hardened steel jaws provide ultimate gripping power

• Knurled head screw allows you to adjust the jaw opening and clamping pressure to suit your needs

Typical Applications

• Construction

• Engineering

• Automotive

• Plumbing

Features and Benefits

• Heavy duty rolled chrome vanadium steel construction makes for a durable product

• Comfort grip improves user grip, comfort and control when using

• Locks securely in place to allow for a hands free operation

• Quick release lever allows you to easily disengage the tool

• Drop forged hardened steel jaws provide ultimate gripping power

• Knurled head screw allows you to adjust the jaw opening and clamping pressure to suit your needs

Typical Applications

• Construction

• Engineering

• Automotive

• Plumbing

Download

Produk Lainnya

Indexa FC401275 M12x75mm T-SLOT BOLT

FC40 - T-Slot Bolt

Material: Medium Carbon Steel.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

Material: Medium Carbon Steel.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

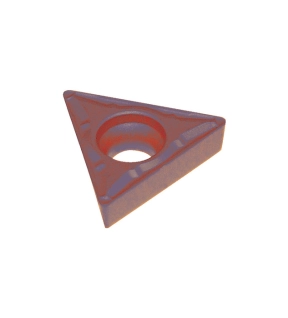

Yamaloy TCMT 16T304-PM, Turning Insert, Grade QX500, Cermet, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grade QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Yamaloy APXT (APKT) 1604PDTR, Milling Insert, Carbide, Grade QP30P

APXT(APKT) 85° parallelogram milling inserts feature a PVD coated substrate ideal for milling steel and stainless steel.

Features and Benefits

• PVD coating for improved heat and wear resistance

• (P10-P35) grade ideal for milling steels and some stainless steels

Typical Applications

• Milling

• Steel

• Stainless steel

Standards

• Insert Grade QP30P

(P10-P35)

Features and Benefits

• PVD coating for improved heat and wear resistance

• (P10-P35) grade ideal for milling steels and some stainless steels

Typical Applications

• Milling

• Steel

• Stainless steel

Standards

• Insert Grade QP30P

(P10-P35)

Sherwood Jobber Drill, 13.5mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN