Abrasive

York Flap Wheel Set, 10-25 x 10-25mm, P120/P60/P80, Aluminium Oxide, 8 Pack

Shaft mounted abrasive flap wheels are ideally suited for stock removal, deburring, cleaning, blending and finishing on a wide range of materials.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Suitable for portable power tools, including die grinders, flexible shafts and drills

• Ideal for removal of rust, cleaning up welds and sanding wood prior to painting

• Versatile - Can be used on metal, wood, plastic and fiberglass

Notes

• Always ensure that the speed of the air tool never exceeds the maximum operating speed of the consumable.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Suitable for portable power tools, including die grinders, flexible shafts and drills

• Ideal for removal of rust, cleaning up welds and sanding wood prior to painting

• Versatile - Can be used on metal, wood, plastic and fiberglass

Notes

• Always ensure that the speed of the air tool never exceeds the maximum operating speed of the consumable.

Download

Produk Lainnya

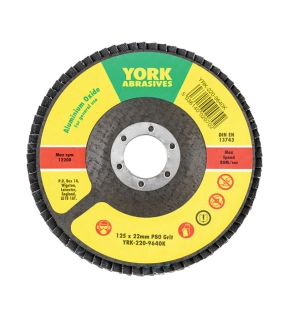

York Flap Disc, 125 x 22.23mm, Conical (Type 29), P80, Aluminium Oxide

Conical flap discs are a high performance alternative to sanding discs where surface finish is important. On light gauge sheet metal, the overlapped abrasive strips slowly wear away revealing fresh abrasive.

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

Kennedy A38 MOUNTED POINT

High-quality 'A' Shape Mounted Points - with a Shank Diameter of 6mm.

Features and Benefits

• All points are aluminium oxide with 'rubenite™' as standard, providing vastly improved durability & reliability

• Available in a wide range of shapes and sizes to suit every need

Typical Applications

• Suitable for portable die and straight hand grinders

• For all general purpose grinding and deburring on steels and most metals

Notes

• Shank diameters are metric as listed below with inch sizes available on request

• Maximum speeds are quoted assuming that collet to back of point does not exceed 12.7mm (1/2") and are for guidance only

Features and Benefits

• All points are aluminium oxide with 'rubenite™' as standard, providing vastly improved durability & reliability

• Available in a wide range of shapes and sizes to suit every need

Typical Applications

• Suitable for portable die and straight hand grinders

• For all general purpose grinding and deburring on steels and most metals

Notes

• Shank diameters are metric as listed below with inch sizes available on request

• Maximum speeds are quoted assuming that collet to back of point does not exceed 12.7mm (1/2") and are for guidance only

York 24mm Brass, Crimped Wire Flat End De-carbonising Brush - 30SWG

Rotary wire brush for hard to reach areas such as drilled holes, recesses and corners. For removal of burrs, rust and paint.

• Very flexible in use

• Very flexible in use

York Coated Sheet, 230 x 280mm, Silicon Carbide, P400, Wet & Dry

These abrasive paper sheets have silicon carbide, waterproof-resin bonded to paper. They are suitable for wet and dry use, making them versatile. There are a variety of grades in this range of sheets.

Features and Benefits

• Silicon carbide

• Ideal for wet and dry use

• Waterproof resin

Typical Applications

• Polishing

• Finishing

• Metals

• Plastics

• Paintwork

• Ceramics

Features and Benefits

• Silicon carbide

• Ideal for wet and dry use

• Waterproof resin

Typical Applications

• Polishing

• Finishing

• Metals

• Plastics

• Paintwork

• Ceramics