kategori Products

BRAND

Abrasive

**If you don't find the product you are looking for, please chat admin via WhatsApp to check the availability of the item

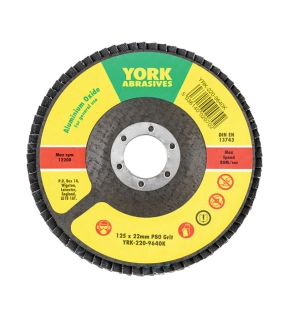

York Flap Disc, 125 x 22.23mm, Conical (Type 29), P80, Aluminium Oxide

Conical flap discs are a high performance alternative to sanding discs where surface finish is important. On light gauge sheet metal, the overlapped abrasive strips slowly wear away revealing fresh abrasive.

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

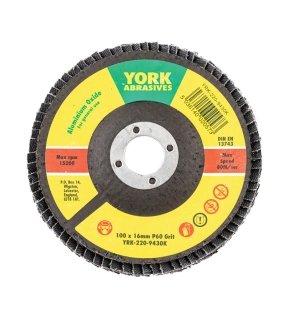

York Flap Disc, 100 x 16mm, Conical (Type 29), P60, Aluminium Oxide

Conical flap discs are a high performance alternative to sanding discs where surface finish is important. On light gauge sheet metal, the overlapped abrasive strips slowly wear away revealing fresh abrasive.

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

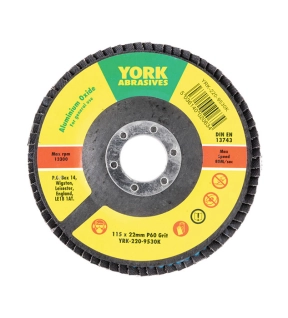

York Flap Disc, 100 x 16mm, Conical (Type 29), P36, Aluminium Oxide

Conical flap discs are a high performance alternative to sanding discs where surface finish is important. On light gauge sheet metal, the overlapped abrasive strips slowly wear away revealing fresh abrasive.

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

Features and Benefits

• The overlap design reduces clogging and ensures the disc always cuts effectively and

• Provides a consistent finish throughout disc life

• No backing pads needed

Notes

• Safe to use at 80m/s on any grinder

Standards

EN12413

York Cartridge Roll, Straight, 25 x 9.5mm, P80, Aluminium Oxide

For fast cutting on contours and hard-to-reach areas, these aluminium oxide cartridge rolls are a long-lasting and cost-effective choice. Ideal for deburring and metal removal, higher grits can also be used for blending and polishing applications.

Features and Benefits

• Spiral wound abrasive constantly exposes a new abrasive surface for product longevity

• Available in a range of roll sizes and grits to suit any application

• Straight form allows for consistent finishing

Typical Applications

• Flash removal

• Edge breaking

• Machine tool mark removal

• Polishing and finishing

Features and Benefits

• Spiral wound abrasive constantly exposes a new abrasive surface for product longevity

• Available in a range of roll sizes and grits to suit any application

• Straight form allows for consistent finishing

Typical Applications

• Flash removal

• Edge breaking

• Machine tool mark removal

• Polishing and finishing

York Cartridge Roll, Straight, 38 x 9.5mm, P80, Aluminium Oxide

For fast cutting on contours and hard-to-reach areas, these aluminium oxide cartridge rolls are a long-lasting and cost-effective choice. Ideal for deburring and metal removal, higher grits can also be used for blending and polishing applications.

Features and Benefits

• Spiral wound abrasive constantly exposes a new abrasive surface for product longevity

• Available in a range of roll sizes and grits to suit any application

• Straight form allows for consistent finishing

Typical Applications

• Flash removal

• Edge breaking

• Machine tool mark removal

• Polishing and finishing

Features and Benefits

• Spiral wound abrasive constantly exposes a new abrasive surface for product longevity

• Available in a range of roll sizes and grits to suit any application

• Straight form allows for consistent finishing

Typical Applications

• Flash removal

• Edge breaking

• Machine tool mark removal

• Polishing and finishing

York 30x5mm Shaft Mounted Rotary Wire Brushes 30SWG.

Circular brushes with shaft are small diameter brushes and are good to be used for drill machines. Normally the RPM is 4500. It's good for both Professional and do-it-yourself work.

Features and Benefits

• High quality, durable crimped wire bristles

• Provides a safe, secure fit

Typical Applications:

• Remove paint and other coatings, including rust and scale from all types of steel work-pieces and oxide layers from stainless-steel and non-ferrous metals

• Creating metallic cleaning surfaces

• Cleaning tool dies

• De-burring castings

• Matt finishing of metal surfaces

Features and Benefits

• High quality, durable crimped wire bristles

• Provides a safe, secure fit

Typical Applications:

• Remove paint and other coatings, including rust and scale from all types of steel work-pieces and oxide layers from stainless-steel and non-ferrous metals

• Creating metallic cleaning surfaces

• Cleaning tool dies

• De-burring castings

• Matt finishing of metal surfaces

York 30x12mm Shaft Mounted Rotary Wire Brushes 30SWG.

Circular brushes with shaft are small diameter brushes and are good to be used for drill machines. Normally the RPM is 4500. It's good for both Professional and do-it-yourself work.

Features and Benefits

• High quality, durable crimped wire bristles

• Provides a safe, secure fit

Typical Applications:

• Remove paint and other coatings, including rust and scale from all types of steel work-pieces and oxide layers from stainless-steel and non-ferrous metals

• Creating metallic cleaning surfaces

• Cleaning tool dies

• De-burring castings

• Matt finishing of metal surfaces

Features and Benefits

• High quality, durable crimped wire bristles

• Provides a safe, secure fit

Typical Applications:

• Remove paint and other coatings, including rust and scale from all types of steel work-pieces and oxide layers from stainless-steel and non-ferrous metals

• Creating metallic cleaning surfaces

• Cleaning tool dies

• De-burring castings

• Matt finishing of metal surfaces

York Flap Wheel, 30 x 15mm, P60, Aluminium Oxide, 3mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting. Recessed hub design for maximum access in tight corners.

Applications:

• Final finishing of metal surfaces.

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels.

• Edge blending and cleaning. Surface preparation prior to painting and plating.

• Can be used on metal, wood, plastic and fibreglass.

IMAGE IS FOR ILLUSTRATIVE PURPOSES ONLY. PLEASE REFER TO PRODUCT DESCRIPTION

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting. Recessed hub design for maximum access in tight corners.

Applications:

• Final finishing of metal surfaces.

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels.

• Edge blending and cleaning. Surface preparation prior to painting and plating.

• Can be used on metal, wood, plastic and fibreglass.

IMAGE IS FOR ILLUSTRATIVE PURPOSES ONLY. PLEASE REFER TO PRODUCT DESCRIPTION

York Flap Wheel Set, 10-25 x 10-25mm, P120/P60/P80, Aluminium Oxide, 8 Pack

Shaft mounted abrasive flap wheels are ideally suited for stock removal, deburring, cleaning, blending and finishing on a wide range of materials.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Suitable for portable power tools, including die grinders, flexible shafts and drills

• Ideal for removal of rust, cleaning up welds and sanding wood prior to painting

• Versatile - Can be used on metal, wood, plastic and fiberglass

Notes

• Always ensure that the speed of the air tool never exceeds the maximum operating speed of the consumable.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Suitable for portable power tools, including die grinders, flexible shafts and drills

• Ideal for removal of rust, cleaning up welds and sanding wood prior to painting

• Versatile - Can be used on metal, wood, plastic and fiberglass

Notes

• Always ensure that the speed of the air tool never exceeds the maximum operating speed of the consumable.

York Flap Wheel Set, 30-60 x 15-30mm, P120/P40/P60/P80, Aluminium Oxide, 8 Pack

Shaft mounted abrasive flap wheels are ideally suited for stock removal, deburring, cleaning, blending and finishing on a wide range of materials.

Features and Benefits

• Recessed hub design allows for maximum access in tight corners

• Suitable for use with portable power tools allowing for use in any situation

• Can be used on metal, wood, plastic, and fibreglass making it the go to for stock removal

Notes

• 6.0mm Shank

Features and Benefits

• Recessed hub design allows for maximum access in tight corners

• Suitable for use with portable power tools allowing for use in any situation

• Can be used on metal, wood, plastic, and fibreglass making it the go to for stock removal

Notes

• 6.0mm Shank

York Flap Wheel, 30 x 15mm, P120, Aluminium Oxide, 3mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting. Recessed hub design for maximum access in tight corners.

Applications:

• Final finishing of metal surfaces.

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels.

• Edge blending and cleaning. Surface preparation prior to painting and plating.

• Can be used on metal, wood, plastic and fibreglass.

IMAGE IS FOR ILLUSTRATIVE PURPOSES ONLY. PLEASE REFER TO PRODUCT DESCRIPTION

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting. Recessed hub design for maximum access in tight corners.

Applications:

• Final finishing of metal surfaces.

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels.

• Edge blending and cleaning. Surface preparation prior to painting and plating.

• Can be used on metal, wood, plastic and fibreglass.

IMAGE IS FOR ILLUSTRATIVE PURPOSES ONLY. PLEASE REFER TO PRODUCT DESCRIPTION

York Flap Wheel, 40 x 30mm, P40, Aluminium Oxide, 6mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only