Pump & Lubricants

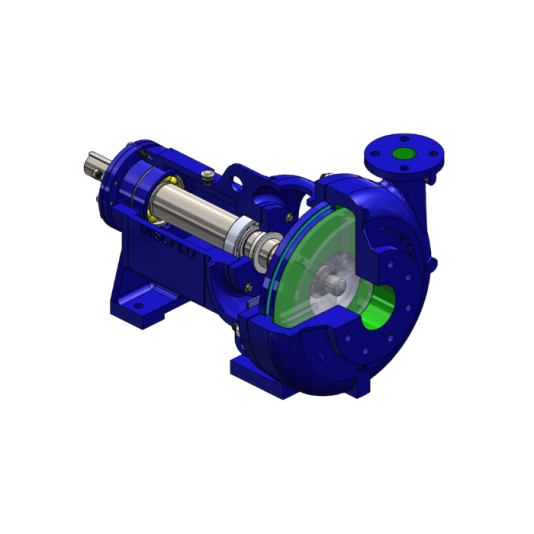

Discflo Glass Lined Pumps

Glass lining is a proven technique for adding a super-durable, smooth, non-stick surface to metal equipment and components.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Download

Produk Lainnya

Kennedy Oil Can, 250cc, Metal

Comprising of an enamel finish and a heavy-gauge, seamless metal body, these oil cans are suited for heavy-duty applications. Each can has a positive force feed brass pump and valve and is supplied with both rigid metal and flexible nylon threaded spouts. Finished in a red colour.

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Features and Benefits

• Enamel finish provides additional protection against wear and tear

• Heavy gauge construction makes for a robust and resilient product

• Supplied with one metal and one flexible nylon spout for versatility

• Available in a range of sizes to suit your requirements

Typical Applications

• Automotive

• Construction

Moresco High Temperature Lubricants

HILUBE

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

Discflo Sump & Dry Pit Pumps

Our sump and dry fit pumps are the clog-free, low cost, long-lived option that outperforms progressive cavity, centrifugal, lobe, and chopper pumps in even the toughest installations. These pumps are not only powerful but incredibly versatile.

Moresco Forging Lubricants

LUBCASTER

FORGING is processing method of creating an objective shape by compressing metallic substance in between molds. LUBCASTER is essential lubricants for producing auto engine components and safety parts.

F-55 : Light yellow transparent mucoid fluid Usable with high dilution by the high adhesion property, suitable to low temperature mold.

F-5110 : Black It is a graphite type. It has high lubricity and extends mold life.

FORGING is processing method of creating an objective shape by compressing metallic substance in between molds. LUBCASTER is essential lubricants for producing auto engine components and safety parts.

F-55 : Light yellow transparent mucoid fluid Usable with high dilution by the high adhesion property, suitable to low temperature mold.

F-5110 : Black It is a graphite type. It has high lubricity and extends mold life.