Pump & Lubricants

Kennedy Hydraulic Nipple, 90°, 1/8" BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Download

Produk Lainnya

Kennedy 20LTR HEAVY DUTY STEEL JERRY CAN (GREEN)

Manufactured from 16 swg steel. Suitable for storing petrol. Suitable for storing and transportation of diesel, paraffin and motor oil. With lever type safety sealing cap and integral carrying handle. Painted outside and phosphated internally.

Features and Benefits

• Strong, ultra-durable material - made from 16 swg steel

• With lever type safety sealing cap and integral carrying handle

• Painted outside and phosphated internally

Notes

• UN Approved, Class 3

Features and Benefits

• Strong, ultra-durable material - made from 16 swg steel

• With lever type safety sealing cap and integral carrying handle

• Painted outside and phosphated internally

Notes

• UN Approved, Class 3

Kennedy Red-Hot-Dip Hot Dip, Bar, Amber, 1 Pcs

Hot dip strippable plastic coating moulds itself around the component or tool to provide 100% coverage and protect against corrosion and impacts for up to ten years. The protected component can be easily identified through the translucent coating. Simply removed by peeling it off, leaves behind a thin oil film to provide short term protection against corrosion. The removed protective dip can be reused.

Features and Benefits

• Easily moulds around tools and components

• Offers 100% coverage for effective protection against corrosion and impacts

• Long lasting protects for up to 10 years

• Components are easily identifiable thanks to the translucent coating

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

• Reusable for a cost effective solution

Notes

• Each block measures (L)-150mm (H)-50mm (W)-80mm.

• Block weight - 0.50kg

Warning

• Never directly apply heat to melt the protective dip, always use with a suitable melting pot.

Features and Benefits

• Easily moulds around tools and components

• Offers 100% coverage for effective protection against corrosion and impacts

• Long lasting protects for up to 10 years

• Components are easily identifiable thanks to the translucent coating

• Working temperature 130°C to 160°C (for optimum results 140°C to 145°C)

• Reusable for a cost effective solution

Notes

• Each block measures (L)-150mm (H)-50mm (W)-80mm.

• Block weight - 0.50kg

Warning

• Never directly apply heat to melt the protective dip, always use with a suitable melting pot.

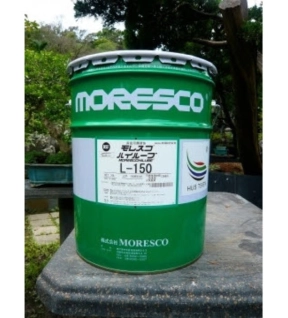

Moresco High Temperature Lubricants

HILUBE

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

Kennedy Hydraulic Connector, 4 Jaw, 1/8" BSP(T), Steel

This 1/8" BSP threaded, 4 jaw hydraulic connector is an effective way of allowing for the controlled flow of lubricants. Securely fastens the grease nipple when in use to ensure minimal slippage.

Features and Benefits

• Manufactured from steel for durability

• Securely grips the grease nipple while in use to control the flow of the lubricant

• Textured in places for easy gripping even with oily or greasy hands

Typical Applications

• Automotive

• Engineering

• Mechanics

Features and Benefits

• Manufactured from steel for durability

• Securely grips the grease nipple while in use to control the flow of the lubricant

• Textured in places for easy gripping even with oily or greasy hands

Typical Applications

• Automotive

• Engineering

• Mechanics