Pump & Lubricants

Moresco High Temperature Lubricants

HILUBE

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

MORESCO-HILUBE, our high temperature lubricating oil, is used in harsh environments as the base oil of greases used with bearings subject to the high temperatures of automotive electrical components and as the lubricating oil used with bearings of machinery such as OA machinery, with bread ovens, and with the drive section of drying furnaces.

L-150 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-320 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-560 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

L-830 : Pale yellow High temperature region of ~270℃.For food machinery(tunnel oven), textile machinery(heat setter) and biaxial stretching machine(film tenter).

Download

Produk Lainnya

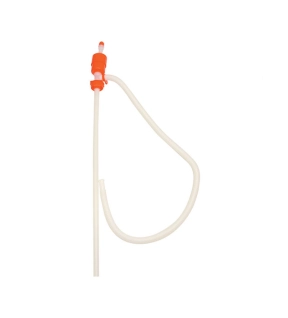

Kennedy SPS/205, Syphon Pump, 205L, Plastic

Available to suit 25 or 205 litre containers, these syphon pumps are an efficient way of controlling and dispensing a host of fluids. Comprised of a flexible plastic outlet and semi-rigid inlet tubes, the hand pumping units incorporate one-way valves. Suited for use with petrol and diesel as well as with non-corrosive liquids. All tubes can be cut to length and are fitted with a threaded bung. Model SPS/25 has a squeeze action and models SPS/205 and SPH/205 have a plunger-type action.

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Features and Benefits

• Tubes can be cut to your desired length to meet your requirements

• Suitable for use with petrol, diesel and all non-corrosive liquids

• Available to suit three sized containers

• Flexible nature allows you to manipulate the pump to your desired position

Typical Applications

• Engineering

• Aquatics

• Automotive

Kennedy Hydraulic Nipple, 45°, 1/8"x28 BSP(T), Steel

For use with Kennedy grease guns and all other hydraulic grease equipment.

Yamoto Side Lever Grease Gun, 500cc, Cartridge Fill

With a comfortable lever grip and offset nozzle, this chrome plated steel lever gun has a 500cc lever and is suited to 400g grease cartridges. Supplied with a flexible rubber hose and suited for medium to heavy greases.

Features and Benefits

• Includes a flexible rubber hose to allow you to begin working immediately

• Manufactured from steel for durability and resilience

• Rubber grip around the lever for comfort and grip when administering lubricants

Typical Applications

• Suited for controlled lubrication of medium and heavy greases to your desired work piece

Features and Benefits

• Includes a flexible rubber hose to allow you to begin working immediately

• Manufactured from steel for durability and resilience

• Rubber grip around the lever for comfort and grip when administering lubricants

Typical Applications

• Suited for controlled lubrication of medium and heavy greases to your desired work piece

Moresco Die Casting Lubricants

Die Realasing Fluids | GRAPHACE

Die casting is a casting method in which molten metals under high pressure are poured into molds and hardened. Our GRAPHACE series of die casting mold releasing lubricants is crucial for releasing heated metals from their molds. GRAPHACE brand die lubricants are used in die cast machines to cast aluminum, magnesium, and zinc parts, which results in better quality parts, improvements to plant productivity and a better working environment.

MS-1 White : liquid Excellent seizure resistance. Available for wide range of machine size at high dilution. Also available as anti-seize agent at low dilution.

GL-6300 Milky white : liquid It is a newly designed release agent considering the adhesion efficiency of release agent components.

Plunger Lubricants | NEOCASTER

During the die casting process, plunger lubricant is necessary to lubricate the sleeves and tips that force the molten metal into the molds. Our NEOCASTER brand plunger lubricant is used in the casting of aluminum parts for automobiles, motorcycles, mobile phones, and similar objects. Using the NEOCASTER plunger lubricant has proven to increase the life of the tip and the shot sleeve as well as improve the casting quality.

PWS-850 : Yellowish brown Good wettability to the metal surface. Stable lubricity at high temperature.

PW-50 : Milky white liquid Available for small and midium-sized machine.

B-200R : Black General purpose type.

RE-77 : Milky white liquid Suitable for small and medium-sized machine.

Die casting is a casting method in which molten metals under high pressure are poured into molds and hardened. Our GRAPHACE series of die casting mold releasing lubricants is crucial for releasing heated metals from their molds. GRAPHACE brand die lubricants are used in die cast machines to cast aluminum, magnesium, and zinc parts, which results in better quality parts, improvements to plant productivity and a better working environment.

MS-1 White : liquid Excellent seizure resistance. Available for wide range of machine size at high dilution. Also available as anti-seize agent at low dilution.

GL-6300 Milky white : liquid It is a newly designed release agent considering the adhesion efficiency of release agent components.

Plunger Lubricants | NEOCASTER

During the die casting process, plunger lubricant is necessary to lubricate the sleeves and tips that force the molten metal into the molds. Our NEOCASTER brand plunger lubricant is used in the casting of aluminum parts for automobiles, motorcycles, mobile phones, and similar objects. Using the NEOCASTER plunger lubricant has proven to increase the life of the tip and the shot sleeve as well as improve the casting quality.

PWS-850 : Yellowish brown Good wettability to the metal surface. Stable lubricity at high temperature.

PW-50 : Milky white liquid Available for small and midium-sized machine.

B-200R : Black General purpose type.

RE-77 : Milky white liquid Suitable for small and medium-sized machine.