kategori Produk

BRAND

Pump & Lubricants

**Jika tidak menemukan produk yang anda cari, silahkan chat admin melalui whatsapp untuk cek ketersediaan barangnya

Discflo Cantilever

Cantilever pumps are ideal for moving abrasive materials and slurries, as only a portion of the pump is located under the fluid. The seals, bearings, bushings, and suction check valves are all outside of the liquid, preventing the material from degrading or interfering with them.

Our cantilever pumps are designed by our engineering team that specializes in handling the toughest pumping jobs. They set the standard for pumping slurries and abrasive materials.

Our cantilever pumps are designed by our engineering team that specializes in handling the toughest pumping jobs. They set the standard for pumping slurries and abrasive materials.

Discflo Glass Lined Pumps

Glass lining is a proven technique for adding a super-durable, smooth, non-stick surface to metal equipment and components.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Discflo glass lined pumps use the dual-coat glass-lining process developed by Vitco, of PA. The glass lining is a mix of fine borosilicate glass, water, and clay, applied to the base metal substrate at high temperature. Vitco’s dual-coat process allows for extra durability and longevity as the base coat forms a strong bond with the base metal and the cover coat provides the non-stick characteristics.

Discflo Horizontal Pumps

• No close tolerances

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations

• Pulsation-free flow

• Laminar flow

• Non-impinging, preventing degradation

• Does not emulsify or damage delicate and shear sensitive products

• Includes in-line, close-coupled, side-by-side, over-under, and self-priming configurations

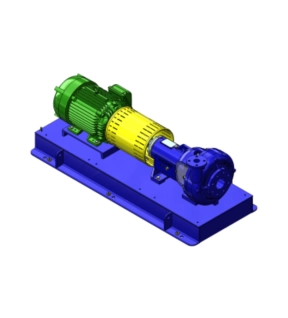

Discflo Multistage Pumps

Our horizontal multistage centrifugal pumps are made of multiple Discpacs, which feed into one another. These stages allow for higher levels of control over the output pressure.

Our horizontal multistage centrifugal pumps are made of multiple Discpacs, which feed into one another. These stages allow for higher levels of control over the output pressure.

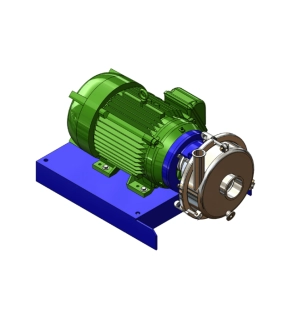

Discflo Sanitary Pumps

Discflo offers two lines of sanitary pumps, the SP Series and MIS Series. Both series meet 3-A sanitary and international hygiene standards and USDA requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

They can be supplied in Clean-in-Place or Steam-in-Place versions, and in a variety of metallurgy to meet the user’s requirements.

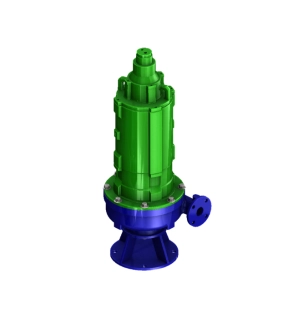

Discflo Submersible Pumps

Our submersible pumps often go to work where centrifugal, progressive cavity, lobe, and chopper pumps have failed. Their unique design and our state-of-the-art technology tackle even the toughest applications with ease.

Discflo Sump & Dry Pit Pumps

Our sump and dry fit pumps are the clog-free, low cost, long-lived option that outperforms progressive cavity, centrifugal, lobe, and chopper pumps in even the toughest installations. These pumps are not only powerful but incredibly versatile.