Measuring Tools

Fluke 789 ProcessMeter™

Double your strength

The Fluke 787 was the first device to combine a DMM and a loop calibrator to give process technicians double the power in one tool. Now even better, range is extended in the Fluke 789 – the ultimate loop calibration multimeter. The Fluke 789 has a 24-Volt supply loop which eliminates the need to take a separate power supply when testing transmitters offline. And with selectable onboard 250-Ohm Hart® resistors, the need to carry separate resistors is eliminated. Now process engineers can do more while carrying far less.

The Fluke 787 was the first device to combine a DMM and a loop calibrator to give process technicians double the power in one tool. Now even better, range is extended in the Fluke 789 – the ultimate loop calibration multimeter. The Fluke 789 has a 24-Volt supply loop which eliminates the need to take a separate power supply when testing transmitters offline. And with selectable onboard 250-Ohm Hart® resistors, the need to carry separate resistors is eliminated. Now process engineers can do more while carrying far less.

Download

Produk Lainnya

Fluke 700G31 Pressure Gauge Calibrator, -14 to 10,000 psi'

Fluke 700G31 Offers

Compatible with most hydraulic and pneumatic test pumps, users can also make use of Fluke's 700G/TRACK Software to upload over 8000 pressure measurements logged in the field.

Features

- Precision pressure measurement from ±10 inH2O to 10,000 psi (20 to 690 bar)

- Absolute pressure measurement ranges 15, 30, 100, 300 psia

- Accuracy to 0.05% of full scale

- Reference class gauge accuracies to 0.04% of reading

- Easy to use, rugged construction for reliable performance

- CSA; Class 1, Div 2, Groups A-D rating

- ATEX rating: II 3 G Ex nA IIB T6

- Combine with the 700PTPK or 700HTPK pump kits for a complete pressure testing solution for up to 600 psi (40 bar) with the PTP-1 pneumatic pump and up to - - 10,000 psi (690 bar) with the HTP-2 hydraulic pump

- Log up to 8493 pressure measurements to memory (requires 700G/TRACK software)

Compatible with most hydraulic and pneumatic test pumps, users can also make use of Fluke's 700G/TRACK Software to upload over 8000 pressure measurements logged in the field.

Features

- Precision pressure measurement from ±10 inH2O to 10,000 psi (20 to 690 bar)

- Absolute pressure measurement ranges 15, 30, 100, 300 psia

- Accuracy to 0.05% of full scale

- Reference class gauge accuracies to 0.04% of reading

- Easy to use, rugged construction for reliable performance

- CSA; Class 1, Div 2, Groups A-D rating

- ATEX rating: II 3 G Ex nA IIB T6

- Combine with the 700PTPK or 700HTPK pump kits for a complete pressure testing solution for up to 600 psi (40 bar) with the PTP-1 pneumatic pump and up to - - 10,000 psi (690 bar) with the HTP-2 hydraulic pump

- Log up to 8493 pressure measurements to memory (requires 700G/TRACK software)

Fluke Pro Electric Pressure Calibrator

Fluke 719Pro Electric Pressure Calibrator sources, simulates, and measures mA signals and more

The 719Pro includes a full functioning loop calibrator that sources, simulates and measures mA signals and more making it the ideal test tool for calibrating high accuracy transmitters, pressure switches and pressure gauges.

Get the ultimate in measurement flexibility with the large backlit screen, which displays three parameters at once:

- Pressure measurement from internal or external sensor

- Sourced/simulated or measured mA values

- Temperature measured by optional RTD probe

The 719Pro includes a full functioning loop calibrator that sources, simulates and measures mA signals and more making it the ideal test tool for calibrating high accuracy transmitters, pressure switches and pressure gauges.

Get the ultimate in measurement flexibility with the large backlit screen, which displays three parameters at once:

- Pressure measurement from internal or external sensor

- Sourced/simulated or measured mA values

- Temperature measured by optional RTD probe

Fluke Fluke 831 Laser Shaft Alignment Tool

Precision laser alignment made easy

The rugged Fluke 831 has an intuitive guided user interface that enables quick and complete shaft alignment without advanced training or complicated programs. And while it’s easy to use, laser alignment with the Fluke 831 is powerful enough for the skilled technician. You can cover more of your machines with all the functionality needed on the plant floor, from thermal growth to user defined tolerances and more.

Reduce costs by avoiding downtime

Misalignment causes at least half of all damage to rotating machinery, studies show. Instead of fixing the problem, teams often just treat the symptoms of misalignment and replace bearings, couplings, and seals because they think alignment takes too long.

Contrary to expectations, laser alignment can be fast and easy. So, every machine that is repaired and overhauled should be aligned – not just a few. Teams that embrace laser alignment can save thousands of dollars per year by avoiding downtime and energy waste and reducing the number of bearings and seals they have to replace.

Key features

• Fast, easy, and precise alignment that adapts to your needs.

• Rugged build and the highest-in-class IP rating.

• Single-laser technology for the fastest, most accurate laser alignment.

• Cloud connection enables real-time collaboration.

• Use up to 8 measurement points to achieve precision alignment on vertical machines.

The rugged Fluke 831 has an intuitive guided user interface that enables quick and complete shaft alignment without advanced training or complicated programs. And while it’s easy to use, laser alignment with the Fluke 831 is powerful enough for the skilled technician. You can cover more of your machines with all the functionality needed on the plant floor, from thermal growth to user defined tolerances and more.

Reduce costs by avoiding downtime

Misalignment causes at least half of all damage to rotating machinery, studies show. Instead of fixing the problem, teams often just treat the symptoms of misalignment and replace bearings, couplings, and seals because they think alignment takes too long.

Contrary to expectations, laser alignment can be fast and easy. So, every machine that is repaired and overhauled should be aligned – not just a few. Teams that embrace laser alignment can save thousands of dollars per year by avoiding downtime and energy waste and reducing the number of bearings and seals they have to replace.

Key features

• Fast, easy, and precise alignment that adapts to your needs.

• Rugged build and the highest-in-class IP rating.

• Single-laser technology for the fastest, most accurate laser alignment.

• Cloud connection enables real-time collaboration.

• Use up to 8 measurement points to achieve precision alignment on vertical machines.

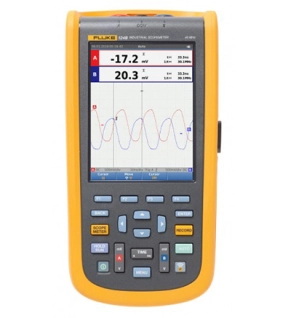

Fluke 124B Industrial ScopeMeter Hand-Held Oscilloscope, 40 MHz

Fluke 124B Offers

Compact and rugged, this oscilloscope is ideal for industrial electrical and electro-mechanical equipment troubleshooting and maintenance applications. Features innovative functions that help technicians troubleshoot faster for quicker results and to keep their systems running smoothly. Additionally, triggering displays waveforms without having to adjust amplitude, timebase, and trigger settings.

Features

- Key measurements: Voltage and power waveforms

- Automatically capture, view and analyze complex waveforms: Fluke Connect and View™ triggering automatically displays waveforms without having to adjust amplitude, timebase and trigger settings, while Intellaset™ technology analyzes the signal and automatically displays critical numerical readings, making troubleshooting faster than ever

- View data locally on the instrument, or via Fluke Connect mobile app

- Dual-input digital oscilloscope and multimeter

- 40 MHz oscilloscope bandwidth

- Two 5000-count true-rms digital multimeters

- Connect-and-View trigger simplicity for hands-off operation

- IntellaSet technology automatically and intelligently adjusts numerical readout based on the measured signal

- Dual-input waveform and meter reading recorder for trending data over extended periods

- Recorder Event Detect captures elusive intermittent signals on repetitive waveforms up to 4 kHz

- Shielded test leads for oscilloscope, resistance and continuity measurements

- Resistance, continuity, diode and capacitance meter measurements

- Power measurements (W, VA, VAR, PF, DPF, Hz)

- Save or recall data and instrument setups

- Store instrument setups defined by a test sequence for routine maintenance or most often used test procedures

- External optically isolated USB interface to transfer, archive and analyze scope or meter data

- Optional WiFi adapter connected to internal USB port to wirelessly transfer information to the PC, laptop or Fluke Connect mobile app

- Rugged design to withstand 3 g Vibration, 30 g shock, and rated IP51 according to EN/IEC60529

- Highest safety rating in the industry: safety rated for CAT IV 600 V

Connect-and-View triggering for an instant, stable display

Oscilloscope users know how difficult triggering can be. Using the wrong settings can lead to unstable waveform captures, and sometimes the wrong measurement data. This instrument's unique Connect-andView triggering technology recognizes signal patterns and automatically sets up the correct triggering to provide a stable, reliable, and repeatable display. Connect-and-View triggering is designed to work with virtually any signal, including motor drives and control signals - without adjusting parameters, or even touching a button. Signal changes are instantly recognized and settings are automatically adjusted, providing a stable display even when measuring multiple test points in quick succession.

IntellaSet/AutoReading

The Auto Readings function with Fluke IntellaSet technology uses proprietary algorithms to intelligently analyze the measured waveform and automatically displays the most appropriate numerical measurements on the screen, so you can get the data you need easier than ever before. As an example, when the measured waveform is a line voltage signal, the Vrms and Hz readings are automatically displayed, whereas if the measured waveform is a square wave, the Vpeak-peak, and Hz readings are automatically displayed. Using IntellaSet technology in conjunction with Connect-and-View automatic triggering you can be sure you're seeing not only the correct waveform but the appropriate numerical reading as well. All without touching a button.

Industrial equipment needs a reliable power supply to operate properly, use the dual input to obtain key power measurements

For single-phase or 3-phase balanced systems, the dual inputs of the Industrial ScopeMeter 120B Series can measure AC+DC RMS voltage on channel A and AC+DC RMS current on channel B. This oscilloscope can then calculate; frequency, phase angle, active power (kW), reactive power (VA or var), power factor (PF), or displacement power factor (DPF) and can also calculate the power values for a 3-phase system where all phases have equal voltage and currents. This applies to both balanced systems and resistive loads.

One test lead to measure multiple electrical parameters

High-frequency waveform, meter, capacitance, and resistance measurements as well as continuity checks are all covered by a single set of shielded test leads. No time is wasted finding or swapping leads.

Fluke Connect mobile app compatibility

Automated industrial machinery is harder than ever to troubleshoot. It's not enough to just know where you have to test, you also have to know what to look for and that can be hard without baseline measurement data or access to subject matter experts. This Fluke Connect Assets wireless system of software and wireless test tools enables technicians to reduce maintenance costs and increase uptime with accurate equipment records and maintenance data that is easy to interpret, and share. Compare and contrast test point measurement data and trends so you can better understand signal characteristics and changes over time. And, by storing maintenance data on the Fluke Cloud you can enable team members to access it from wherever and whenever they need to so you can get advice or approvals in the field and get your systems up and running faster than ever before.

Use the comprehensive recorder modes to help find intermittent faults with ease

The toughest faults to find are those that happen only once in a while-intermittent event. They can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Other factors, like line outages and sags or the starting and stopping of a motor, can also cause intermittent events resulting in equipment shutdowns. When these events happen, you may not be around to see them. But, your Fluke ScopeMeter Test Tool will. You can either plot the minimum and maximum peak measurement values or record the waveform trace. And, with expandable micro SD memory, recording sessions can be done for up to 14 days. This recorder is even more powerful with the addition of Recorder Event Detect, which makes detecting and logging intermittent faults easier than ever. Just set a threshold on a meter reading or scope trace and deviations are tagged as unique events. You no longer need to search through masses of data to pinpoint faults, and can quickly step from one tagged event to the next, while still having access to the full data

Compact and rugged, this oscilloscope is ideal for industrial electrical and electro-mechanical equipment troubleshooting and maintenance applications. Features innovative functions that help technicians troubleshoot faster for quicker results and to keep their systems running smoothly. Additionally, triggering displays waveforms without having to adjust amplitude, timebase, and trigger settings.

Features

- Key measurements: Voltage and power waveforms

- Automatically capture, view and analyze complex waveforms: Fluke Connect and View™ triggering automatically displays waveforms without having to adjust amplitude, timebase and trigger settings, while Intellaset™ technology analyzes the signal and automatically displays critical numerical readings, making troubleshooting faster than ever

- View data locally on the instrument, or via Fluke Connect mobile app

- Dual-input digital oscilloscope and multimeter

- 40 MHz oscilloscope bandwidth

- Two 5000-count true-rms digital multimeters

- Connect-and-View trigger simplicity for hands-off operation

- IntellaSet technology automatically and intelligently adjusts numerical readout based on the measured signal

- Dual-input waveform and meter reading recorder for trending data over extended periods

- Recorder Event Detect captures elusive intermittent signals on repetitive waveforms up to 4 kHz

- Shielded test leads for oscilloscope, resistance and continuity measurements

- Resistance, continuity, diode and capacitance meter measurements

- Power measurements (W, VA, VAR, PF, DPF, Hz)

- Save or recall data and instrument setups

- Store instrument setups defined by a test sequence for routine maintenance or most often used test procedures

- External optically isolated USB interface to transfer, archive and analyze scope or meter data

- Optional WiFi adapter connected to internal USB port to wirelessly transfer information to the PC, laptop or Fluke Connect mobile app

- Rugged design to withstand 3 g Vibration, 30 g shock, and rated IP51 according to EN/IEC60529

- Highest safety rating in the industry: safety rated for CAT IV 600 V

Connect-and-View triggering for an instant, stable display

Oscilloscope users know how difficult triggering can be. Using the wrong settings can lead to unstable waveform captures, and sometimes the wrong measurement data. This instrument's unique Connect-andView triggering technology recognizes signal patterns and automatically sets up the correct triggering to provide a stable, reliable, and repeatable display. Connect-and-View triggering is designed to work with virtually any signal, including motor drives and control signals - without adjusting parameters, or even touching a button. Signal changes are instantly recognized and settings are automatically adjusted, providing a stable display even when measuring multiple test points in quick succession.

IntellaSet/AutoReading

The Auto Readings function with Fluke IntellaSet technology uses proprietary algorithms to intelligently analyze the measured waveform and automatically displays the most appropriate numerical measurements on the screen, so you can get the data you need easier than ever before. As an example, when the measured waveform is a line voltage signal, the Vrms and Hz readings are automatically displayed, whereas if the measured waveform is a square wave, the Vpeak-peak, and Hz readings are automatically displayed. Using IntellaSet technology in conjunction with Connect-and-View automatic triggering you can be sure you're seeing not only the correct waveform but the appropriate numerical reading as well. All without touching a button.

Industrial equipment needs a reliable power supply to operate properly, use the dual input to obtain key power measurements

For single-phase or 3-phase balanced systems, the dual inputs of the Industrial ScopeMeter 120B Series can measure AC+DC RMS voltage on channel A and AC+DC RMS current on channel B. This oscilloscope can then calculate; frequency, phase angle, active power (kW), reactive power (VA or var), power factor (PF), or displacement power factor (DPF) and can also calculate the power values for a 3-phase system where all phases have equal voltage and currents. This applies to both balanced systems and resistive loads.

One test lead to measure multiple electrical parameters

High-frequency waveform, meter, capacitance, and resistance measurements as well as continuity checks are all covered by a single set of shielded test leads. No time is wasted finding or swapping leads.

Fluke Connect mobile app compatibility

Automated industrial machinery is harder than ever to troubleshoot. It's not enough to just know where you have to test, you also have to know what to look for and that can be hard without baseline measurement data or access to subject matter experts. This Fluke Connect Assets wireless system of software and wireless test tools enables technicians to reduce maintenance costs and increase uptime with accurate equipment records and maintenance data that is easy to interpret, and share. Compare and contrast test point measurement data and trends so you can better understand signal characteristics and changes over time. And, by storing maintenance data on the Fluke Cloud you can enable team members to access it from wherever and whenever they need to so you can get advice or approvals in the field and get your systems up and running faster than ever before.

Use the comprehensive recorder modes to help find intermittent faults with ease

The toughest faults to find are those that happen only once in a while-intermittent event. They can be caused by bad connections, dust, dirt, corrosion, or simply broken wiring or connectors. Other factors, like line outages and sags or the starting and stopping of a motor, can also cause intermittent events resulting in equipment shutdowns. When these events happen, you may not be around to see them. But, your Fluke ScopeMeter Test Tool will. You can either plot the minimum and maximum peak measurement values or record the waveform trace. And, with expandable micro SD memory, recording sessions can be done for up to 14 days. This recorder is even more powerful with the addition of Recorder Event Detect, which makes detecting and logging intermittent faults easier than ever. Just set a threshold on a meter reading or scope trace and deviations are tagged as unique events. You no longer need to search through masses of data to pinpoint faults, and can quickly step from one tagged event to the next, while still having access to the full data