Cutting Tools

Atlas Workhokders SC105225 55x25x12mm M10 STEP CLAMP

Material: Medium Carbon Steel.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

Download

Produk Lainnya

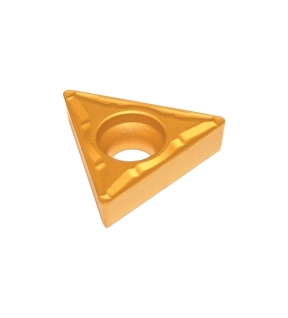

Yamaloy TCMT 16T304-PM, Turning Insert, Grade QX5020, Carbide, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grade QX5020

(ISO P10-P35 M10-M30 K10-K30) CVD Coated.An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grade QX5020

(ISO P10-P35 M10-M30 K10-K30) CVD Coated.An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Sherwood 1/4" DIA. x 4" HSS TOOLBIT

Cut faster, 'stand up' longer and reduce costs. Square and rectangular toolbits supplied with 15° bevelled ends. Parting-off blades supplied with 2° side taper, 10° bevel (top and bottom).

Sherwood Counterbore, 11mm, High Speed Steel, 3 fl, Plain Shank, Uncoated

Plain Shank

Spiral flute, 3 flute. Medium duty. Used for milling of pre-drilled holes to allow bolt or cap head screws to lie flush with the component surface. Manufactured to manufacturers standard

Spiral flute, 3 flute. Medium duty. Used for milling of pre-drilled holes to allow bolt or cap head screws to lie flush with the component surface. Manufactured to manufacturers standard

Indexa L163FA LATCH TYPE TOGGLE CLAMP

Suitable for sealing chamber doors or mould closures, the latch type toggle clamp from Indexa® is a handy addition to your toolkit. The latched bolts are threaded to allow easy adjustment and provide positive connection with the latch plate.

Features and Benefits

• Threaded latched bolts for easy adjustment

• Zinc plated body and linkage components are corrosion resistant

• Red vinyl hand grip for operator comfort

Typical Applications

• Suitable for sealing chamber doors or mould closures

Features and Benefits

• Threaded latched bolts for easy adjustment

• Zinc plated body and linkage components are corrosion resistant

• Red vinyl hand grip for operator comfort

Typical Applications

• Suitable for sealing chamber doors or mould closures