Cutting Tools

SwissBurr F20, High Speed Steel, Hand Deburring Countersink, 20mm x 90°

SwissBurr hand deburring tools are a fast effective and efficient way of deburring holes, slots and edges. Swiss Burr is a totally modular system of interchangeable handles, holders and blades designed to cover all applications. A choice of HSS or carbide blades, countersinks and scrapers are available to suit your specific application. Swiss Burr blades are also interchangeable with commonly available brands including Kennedy, Noga, Ruko, Seco, Snap-Tap and Stellram.

F12 - HSS countersink for hole edges up to 12mm dia.

F20 - HSS countersink for hole edges up to 20mm dia.

F30 - HSS countersink for hole edges up to 30mm dia.

F12 - HSS countersink for hole edges up to 12mm dia.

F20 - HSS countersink for hole edges up to 20mm dia.

F30 - HSS countersink for hole edges up to 30mm dia.

Download

Produk Lainnya

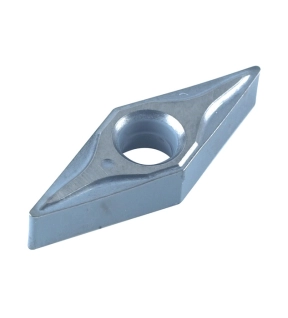

Yamaloy VNMG 12T304-NF1, Turning Insert, Grade QX500, Cermet, 35° Rhombic

VNMG Turning Inserts

35° Rhombic Insert

Insert Grades QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: NFI. Application: Finish.

35° Rhombic Insert

Insert Grades QX500

(ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

Chip Breaker: NFI. Application: Finish.

Sherwood Jobber Drill, 2.5mm, Normal Helix, High Speed Steel, Bright

Series J100 - Metric general purpose drills for steels, cast steel, grey cast iron, malleable cast iron, nickel brass, aluminium alloy and graphite.

Features and Benefits

• High speed steel construction with bright finish for increased toughness

• Supplied in the as-ground condition for use with non ferrous materials

Standards

• Manufactured to BS 328/DIN338RN

Notes

• Drills with a bright finish are supplied in the as-ground condition and such tools are used generally in the machining of non-ferrous materials.

Features and Benefits

• High speed steel construction with bright finish for increased toughness

• Supplied in the as-ground condition for use with non ferrous materials

Standards

• Manufactured to BS 328/DIN338RN

Notes

• Drills with a bright finish are supplied in the as-ground condition and such tools are used generally in the machining of non-ferrous materials.

SwissBurr E200 TiN, High Speed Steel, Hand Deburring Blade

SwissBurr hand deburring tools are a fast effective and efficient way of deburring holes, slots and edges. Its a totally modular system of interchangeable handles, holders and blades is designed to cover all applications. A choice of HSS or carbide blades, countersinks and scrapers are available to suit your specific application. SwissBurr blades are also interchangeable with commonly available brands including Kennedy, Noga, Ruko, Seco, Snap-Tap and Stellram.

Features and Benefits

• Modular system of interchangeable handles, holders and blades

• For deburring holes, slots and edges on metals and plastics

• Interchangeable with commonly available brands

Specfications

• E100 - HSS heavy duty blade for use on straight and hole edges, for deburring materials with spiral chips

• E101 - HSS heavy duty blade for use on straight and hole edges, E style shank with B10 cutting geometry, for use on materials with spiral chips and holes with minimum diameter of 2mm

• E111 - HSS heavy duty blade is for straight and hole edge deburring, for use on materials with spiral chips, steel, aluminium, copper and plastic

• E200 - HSS heavy duty blade for use on straight and hole edges. Blade design allows clockwise and anti-clockwise movement for use on materials with powdery chips

• E202 - HSS heavy duty blade for use on straight and hole edges. E style shank with B20 cutting geometry. Blade design allows clockwise and anti clockwise movement for use on materials with powdery chips

• E300 - HSS heavy duty blade for use on cross-hole and both edges. Blade will simultaneously deburr the inside and outside of the hole up to 6.mm thick. For use on materials with spiral chips

• E350 - HSS heavy duty blade for use on straight and hole edges. Blade design allows clockwise and anti-clockwise movement for use on materials with powdery chips

• E600 - Heavy duty blade for removing burrs from the back edges of holes up to 20mm thick

Typical Applications

• Metal

• Wood

• Plastics

• Deburring

Notes

• For use with "E" holder

• Blades sold Individually

Features and Benefits

• Modular system of interchangeable handles, holders and blades

• For deburring holes, slots and edges on metals and plastics

• Interchangeable with commonly available brands

Specfications

• E100 - HSS heavy duty blade for use on straight and hole edges, for deburring materials with spiral chips

• E101 - HSS heavy duty blade for use on straight and hole edges, E style shank with B10 cutting geometry, for use on materials with spiral chips and holes with minimum diameter of 2mm

• E111 - HSS heavy duty blade is for straight and hole edge deburring, for use on materials with spiral chips, steel, aluminium, copper and plastic

• E200 - HSS heavy duty blade for use on straight and hole edges. Blade design allows clockwise and anti-clockwise movement for use on materials with powdery chips

• E202 - HSS heavy duty blade for use on straight and hole edges. E style shank with B20 cutting geometry. Blade design allows clockwise and anti clockwise movement for use on materials with powdery chips

• E300 - HSS heavy duty blade for use on cross-hole and both edges. Blade will simultaneously deburr the inside and outside of the hole up to 6.mm thick. For use on materials with spiral chips

• E350 - HSS heavy duty blade for use on straight and hole edges. Blade design allows clockwise and anti-clockwise movement for use on materials with powdery chips

• E600 - Heavy duty blade for removing burrs from the back edges of holes up to 20mm thick

Typical Applications

• Metal

• Wood

• Plastics

• Deburring

Notes

• For use with "E" holder

• Blades sold Individually

Indexa FC401275 M12x75mm T-SLOT BOLT

FC40 - T-Slot Bolt

Material: Medium Carbon Steel.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.

Material: Medium Carbon Steel.

Hardness: HRC 32 - 38.

Surface Finish: Black Oxide.