Cutting Tools

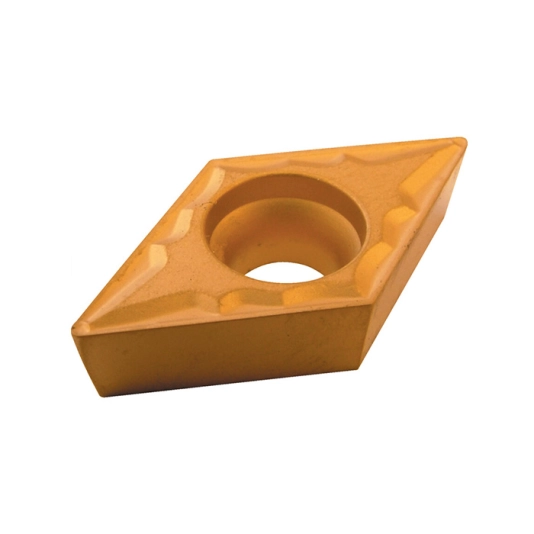

Yamaloy DCMT 11T304-PM, Turning Insert, Grade QX520, Carbide, 55° Rhombic

DCMT Turning Inserts

55° Rhombic Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

55° Rhombic Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Download

Produk Lainnya

Sherwood Jobber Drill, 6.5mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Yamaloy TCMT 110204-PM, Turning Insert, Grade QX520, Carbide, Triangle

TCMT Turning Inserts

60° Triangular Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

60° Triangular Insert

Insert Grades QX520

(ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

Chip Breaker: PM. Application: Med Cut.

Sherwood Jobber Drill, 6mm, Normal Helix, High Speed Steel, Black Oxide

The J100 Series are general purpose HSS straight shank drills with a black oxide finish. Ideal for applications involving steel (including cast steel) cast iron (including malleable cast iron) as well as nickel, brass aluminium alloys and graphite. Their 118° point allows for precise hole alignment and reliable cutting performance whilst the black oxide coating helps reduce heat by retaining coolant on the tool surface. The coating also helps reduce the risk of the tool staining.

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Features and Benefits

• High speed steel construction for increased tool durability

• Point angle of 118° for precise holemaking and precision cutting

• Black oxide coating helps aid chip flow, reduce heat and prevent staining

• Ideal for applications involving steel, iron, nickel, brass, aluminium alloy and graphite

Typical Applications

• Cutting and drilling

• Ferrous materials

• Steel

• Iron

• Nickel

• Brass

• Aluminium alloy

• Graphite

Notes

• Available in sizes 0.25mm -20.00mm

Standards

• Manufactured to BS 328/DIN338RN

Kennedy Jobber Drill, 2mm, Normal Helix, Cobalt High Speed Steel, Bronze Oxide

The Kennedy range of HSS-Co heavy duty straight shank jobber drills provide durable and reliable cutting performance at high temperatures and speeds thanks to the addition of 5% cobalt to their alloys. Their toughness and heat resistance allows them to to drill steels with tensile strength up to 1,400 N/mm², very hard bronze, stainless steels as well as heat and acid resistant steels.

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm

Long lasting the cutting edges retain their sharpness for longer periods, maximising performance and productivity, whilst also being resistant to corrosion.

Features and Benefits

• Made with a 5% cobalt alloy for optimal performance at high speeds and temperatures

• Allows for optimal cutting of metals up to a tensile strength up to 1,400 N/mm²

• 135° point angle for precise hole making and efficient cutting

• For applications including steel, bronze, stainless and acid resistant steels

• Extended lifespan on cutting edge, required less sharpening over time

• Excellent corrosion resistance extends the lifespan of the tool

Standards

• Manufacturing Standard: BS 328, DIN 338B

Typical Applications

• Cutting and drilling

• Hard metals

• Stainless steel

• Bronze

Notes

• Available in sizes 1-13mm