Abrasive

Sealey GRINDING STONE Ø150 X20MM Ø32(Ø13)MM BORE A60P FINE

These high-quality bench grinding wheels are ideal for a wide range of material applications. Designed to fit on all leading brand machines, they provide an excellent performance to all projects.

Features and Benefits

• Suitable for all-purpose applications

• High hardness levels for consistent results

Typical Applications

• Sharpening

• Deburring

• Rust removal

Standards

• EN 12413

Warnings

• Not permitted for wet grinding

Notes

• All 150mm grinding stones fit 13mm bore sizes with 32-13mm diameter reduction bushes supplied where necessary

Features and Benefits

• Suitable for all-purpose applications

• High hardness levels for consistent results

Typical Applications

• Sharpening

• Deburring

• Rust removal

Standards

• EN 12413

Warnings

• Not permitted for wet grinding

Notes

• All 150mm grinding stones fit 13mm bore sizes with 32-13mm diameter reduction bushes supplied where necessary

Download

Produk Lainnya

York Flap Wheel, 50 x 25mm, P80, Aluminium Oxide, 6mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Kennedy PA631, Coated Belt, 100 x 915mm, P120, Aluminium Oxide

The Kennedy resin bonded aluminium oxide abrasive belts are designed for use in industrial applications, combining durability and flexibility to ensure a long life and outstanding performance. The ranges of grits allows for use on a range of surfaces from wood to metal.

Features and Benefits

• Combining durability and flexibility allows for a long life and outstanding performance in any situation

• A wide range of grits available to allow usage on a range of surfaces from wood to metal

Features and Benefits

• Combining durability and flexibility allows for a long life and outstanding performance in any situation

• A wide range of grits available to allow usage on a range of surfaces from wood to metal

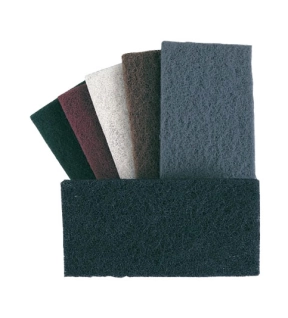

York Non-Woven Hand Pad, 155 x 225mm, Non Abrasive, General Purpose

York non-woven fibre hand pads are ideal for cleaning, blending and finishing applications. They are available in a range grades from non abrasive to coarse to suit any application. They are supplied in packs of 10 to ensure they can get you through any project.

Features and Benefits

• Available in a range of grades to suit any application

• Supplied in packs of 10 to ensure they can get you through any project

Features and Benefits

• Available in a range of grades to suit any application

• Supplied in packs of 10 to ensure they can get you through any project

York 3/8in Double Spiral Power Brush c/w Universal - Brass.

For machine use in cleaning interior of tubes and removing soft deposits in condenser and heat exchanger equipment.

Features and Benefits

• 1/4in. straight cylindrical shank arbor

• For use in a pistol type corded or cordless power drill

• Available in brass coated open twist, sizes ¼in. to 1in.

Features and Benefits

• 1/4in. straight cylindrical shank arbor

• For use in a pistol type corded or cordless power drill

• Available in brass coated open twist, sizes ¼in. to 1in.