Abrasive

York Flap Wheel, 40 x 20mm, P40, Aluminium Oxide, 6mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Download

Produk Lainnya

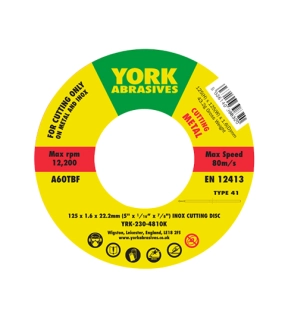

York Cutting Disc, 60-Fine, 125 x 1.6 x 22.23 mm, Type 41, Aluminium Oxide

York Inox cutting discs are perfect for efficiently cutting metal with minimum material removal and machine wear, thanks to their thin profile. They are suitable for use with all appropriate handheld grinders and can even be used on stainless steel.

There are a wide range of sizes available, with 180mm and 230mm sizes suitable for use on circular saws.

Features and Benefits

• Thin profile allows for quick and efficient cuts with minimal material removal and machine wear

• Wide range of sizes allow for usage on a variety of appropriate handheld grinders and larger sizes can even be used in circular saws

Notes

• Cutting discs must never be used for grinding and must always be presented to the work piece at an angle of 90°

There are a wide range of sizes available, with 180mm and 230mm sizes suitable for use on circular saws.

Features and Benefits

• Thin profile allows for quick and efficient cuts with minimal material removal and machine wear

• Wide range of sizes allow for usage on a variety of appropriate handheld grinders and larger sizes can even be used in circular saws

Notes

• Cutting discs must never be used for grinding and must always be presented to the work piece at an angle of 90°

Sealey GRINDING STONE Ø150 X20MM Ø32(Ø13)MM BORE A60P FINE

These high-quality bench grinding wheels are ideal for a wide range of material applications. Designed to fit on all leading brand machines, they provide an excellent performance to all projects.

Features and Benefits

• Suitable for all-purpose applications

• High hardness levels for consistent results

Typical Applications

• Sharpening

• Deburring

• Rust removal

Standards

• EN 12413

Warnings

• Not permitted for wet grinding

Notes

• All 150mm grinding stones fit 13mm bore sizes with 32-13mm diameter reduction bushes supplied where necessary

Features and Benefits

• Suitable for all-purpose applications

• High hardness levels for consistent results

Typical Applications

• Sharpening

• Deburring

• Rust removal

Standards

• EN 12413

Warnings

• Not permitted for wet grinding

Notes

• All 150mm grinding stones fit 13mm bore sizes with 32-13mm diameter reduction bushes supplied where necessary

York Flap Wheel, 30 x 15mm, P150, Aluminium Oxide, 6mm Shank

Shaft mounted flap wheels can be used in portable air or electric power tools, including die grinders, flexible shafts and drills.

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

Used for a wide range of applications such as removal of rust, cleaning up welds and sanding wood prior to painting.

Features and Benefits

• Recessed hub design for maximum access in tight corners

• Highly efficient design

• Durable construction means the flap wheels last longer than others on the market

Typical Applications

• Final finishing of metal surfaces

• Miss-match removal and de-burring on machined components.

• Blending and finishing tool, tubes, dies, moulds, channels

• Edge blending and cleaning. Surface preparation prior to painting and plating

• Can be used on metals, woods, plastic and fibreglass

Notes

• Images are for illustration purposes only

3M Convuluted Deburring Wheel, 152 x 25 x 25mm, Fine, Silicon Carbide, 18768

DB-WL

Non-woven open mesh nylon abrasive provides a consistent finish and light stock removal. Non-aggressive wheel structure makes it perfect for deburring, blending, cleaning, polishing, deflashing plastics, removing oxides etc.

Suitable for all bench/pedestal grinders and polishers. Eye guards and tool rests are not essential for this product.

Features and Benefits

• Hard density, highly conformable wheel performs effective burr removal without undercutting the workpiece

• Convolute construction keeps the wheel running smooth, producing consistent results over time

• Scotch-Brite™ non-woven material resists loading and continuously supplies fresh abrasives for continuous high performance cutting action

• Resulting finish may negate subsequent conditioning steps

• Minimises heat build up to reduce risk of discolouration and warping on heat sensitive substrates

• Effective for all types of metals, composites, and glass, allowing one wheel to perform more tasks

Non-woven open mesh nylon abrasive provides a consistent finish and light stock removal. Non-aggressive wheel structure makes it perfect for deburring, blending, cleaning, polishing, deflashing plastics, removing oxides etc.

Suitable for all bench/pedestal grinders and polishers. Eye guards and tool rests are not essential for this product.

Features and Benefits

• Hard density, highly conformable wheel performs effective burr removal without undercutting the workpiece

• Convolute construction keeps the wheel running smooth, producing consistent results over time

• Scotch-Brite™ non-woven material resists loading and continuously supplies fresh abrasives for continuous high performance cutting action

• Resulting finish may negate subsequent conditioning steps

• Minimises heat build up to reduce risk of discolouration and warping on heat sensitive substrates

• Effective for all types of metals, composites, and glass, allowing one wheel to perform more tasks